How to Cut, Bend, and Install Perspex Sheets Like a Pro

Perspex sheets, also known as acrylic sheets, are an incredibly versatile material used in residential, commercial, and industrial projects. Whether you’re creating windows, partitions, display cases, signage, or decorative elements, knowing how to cut, bend, and install Perspex sheets properly ensures a professional finish and long-lasting results.

At BHD, we supply high-quality Perspex sheets suitable for a wide range of applications across Kenya. This guide provides a step-by-step walkthrough, tips, and best practices to handle Perspex like a seasoned pro.

What Are Perspex Sheets?

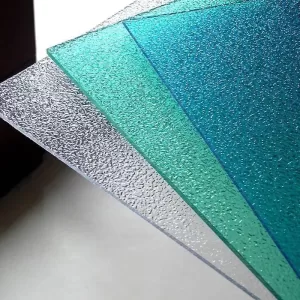

Perspex is a brand name for acrylic sheets, a lightweight and shatter-resistant alternative to glass. Some key features include:

-

Transparency: Crystal-clear or colored options available

-

Durability: Resistant to impact and weather conditions

-

Workability: Can be cut, drilled, and bent without cracking

-

Versatility: Suitable for indoor and outdoor applications

Perspex sheets are often compared to other materials like polycarbonate sheets and glass. While polycarbonate is more impact-resistant, Perspex provides superior optical clarity, making it ideal for aesthetic projects.

Tools You Need to Cut Perspex Sheets

Before you start, gather the right tools to ensure clean cuts and prevent cracking:

-

Hand tools: Fine-tooth hacksaw or utility knife

-

Power tools: Circular saw with a plastic-cutting blade, jigsaw with fine teeth, or table saw

-

Safety equipment: Gloves, safety glasses, and dust mask

-

Measuring tools: Ruler, tape measure, and marking pencil

-

Clamping tools: Workbench clamps or vice to hold sheets securely

Pro Tip: Always place masking tape along the cutting line to reduce chipping and provide a guide for cleaner cuts.

Step-by-Step Guide to Cutting Perspex Sheets

Cutting Perspex requires patience and precision. Here’s a method that works for both beginners and professionals:

1. Measure and Mark

Use a ruler and pencil to measure the dimensions you need. Mark the cutting line with a fine marker or masking tape. Accuracy is key to prevent wasted material.

2. Secure the Sheet

Clamp the sheet firmly on a flat surface. Ensure the cut line is slightly overhanging if using a saw. Stability prevents cracks during cutting.

3. Choose the Right Cutting Tool

-

For thin sheets (up to 3mm): Use a sharp utility knife with scoring technique

-

For medium sheets (3–6mm): Use a fine-tooth hand saw or jigsaw

-

For thick sheets (6mm+): Use a circular saw or table saw with a plastic-specific blade

4. Cut Slowly and Evenly

Avoid forcing the tool. Apply steady pressure and maintain a straight line. For scoring cuts, repeat the score line several times before snapping the sheet along the line.

5. Smooth Edges

After cutting, smooth the edges with sandpaper (180–400 grit) or a deburring tool to remove sharp edges and create a polished finish.

BHD stocks premium Perspex sheets in Nairobi and can advise on sheet thickness and cutting techniques.

How to Bend Perspex Sheets

Bending Perspex can create custom shapes for signage, display cases, and architectural features. There are two main methods: cold bending and hot bending.

Cold Bending

-

Works for thin sheets (up to 2–3mm)

-

Use a bending jig or straight edge

-

Apply steady pressure along the bend line

Tip: Avoid forcing thicker sheets as they may crack.

Hot Bending

-

Required for thicker sheets (3mm+)

-

Use a strip heater or heat gun along the bend line

-

Apply heat evenly until the sheet becomes flexible

-

Bend gradually and clamp into shape until it cools

Learn more about solid polycarbonate sheets for comparison with Perspex bending techniques.

Installing Perspex Sheets Like a Pro

Proper installation ensures durability and aesthetic appeal. Here’s a professional approach:

1. Prepare the Surface

Ensure the installation area is clean, flat, and free from sharp objects that could scratch the sheet.

2. Drill Mounting Holes

-

Use a drill with a fine-tooth bit

-

Drill slightly larger holes than screws to allow thermal expansion

-

Avoid drilling too close to edges to prevent cracks

3. Fasten Sheets

-

Use rubber washers or gaskets to prevent cracking under pressure

-

Tighten screws gently without over-torquing

4. Seal Edges

-

For outdoor installations, use silicone sealant to protect against water ingress

-

For indoor displays, polished edges are often sufficient

5. Maintenance Tips

-

Clean with mild soapy water or plastic cleaner

-

Avoid abrasive tools that may scratch the surface

-

Regular inspections prevent cracks or discoloration

Common Applications of Perspex Sheets

Perspex sheets are used across multiple industries due to their clarity, strength, and flexibility.

Residential

-

Window panes and skylights

-

Cabinet doors and partitions

-

Decorative panels

Commercial

-

Shop signage and display cases

-

Protective barriers in offices and restaurants

-

Interior design features

Industrial

-

Machine guards

-

Laboratory enclosures

-

Control panels and protective shields

Check premium Perspex sheets in Nairobi for a range of sizes suitable for all applications.

Tips for Working With Perspex Like a Pro

-

Always measure twice, cut once to minimize waste

-

Use masking tape to prevent chipping when cutting

-

Heat evenly when bending to avoid bubbles or warping

-

Handle carefully—Perspex is strong but can scratch or crack under impact

-

Choose the right thickness for your project’s load and visibility requirements

Why Buy Perspex Sheets from BHD

BHD provides:

-

High-quality Perspex sheets in various thicknesses and colors

-

Expert advice for cutting, bending, and installation

-

Nationwide delivery across Kenya, including Nairobi, Mombasa, Kisumu, Eldoret, Nakuru, and beyond

We also supply complementary products such as polycarbonate roofing sheets and WPC wall panels for complete construction and renovation solutions.

Final Thoughts & Call to Action

Whether you’re a DIY enthusiast, contractor, or interior designer, mastering cutting, bending, and installing Perspex sheets elevates your projects to professional standards.

For high-quality Perspex sheets in Kenya and expert guidance, visit BHD’s Perspex sheets page or contact us today. We deliver nationwide and provide support to ensure your project is a success.

Contact BHD:

-

Call/WhatsApp: +254 731 217 462 | +254 704 606 131

-

Email: burhanihardwaredealers [at] yahoo.com

-

Visit: BHD, Industrial Area, Funzi Road, Nairobi

Leave a reply