Polycarbonates in Kenyan Market

Polycarbonates in Kenyan Market have emerged as one of the most versatile engineering thermoplastics in Kenya’s construction, automotive, and electronics industries. With their unique combination of strength, transparency, and thermal resistance, these materials are increasingly replacing traditional glass and other plastics in numerous applications. For businesses and consumers in Kenya looking to source high-quality polycarbonates, understanding the differences between Egyptian, Chinese, and embossed varieties can make all the difference in project outcomes.

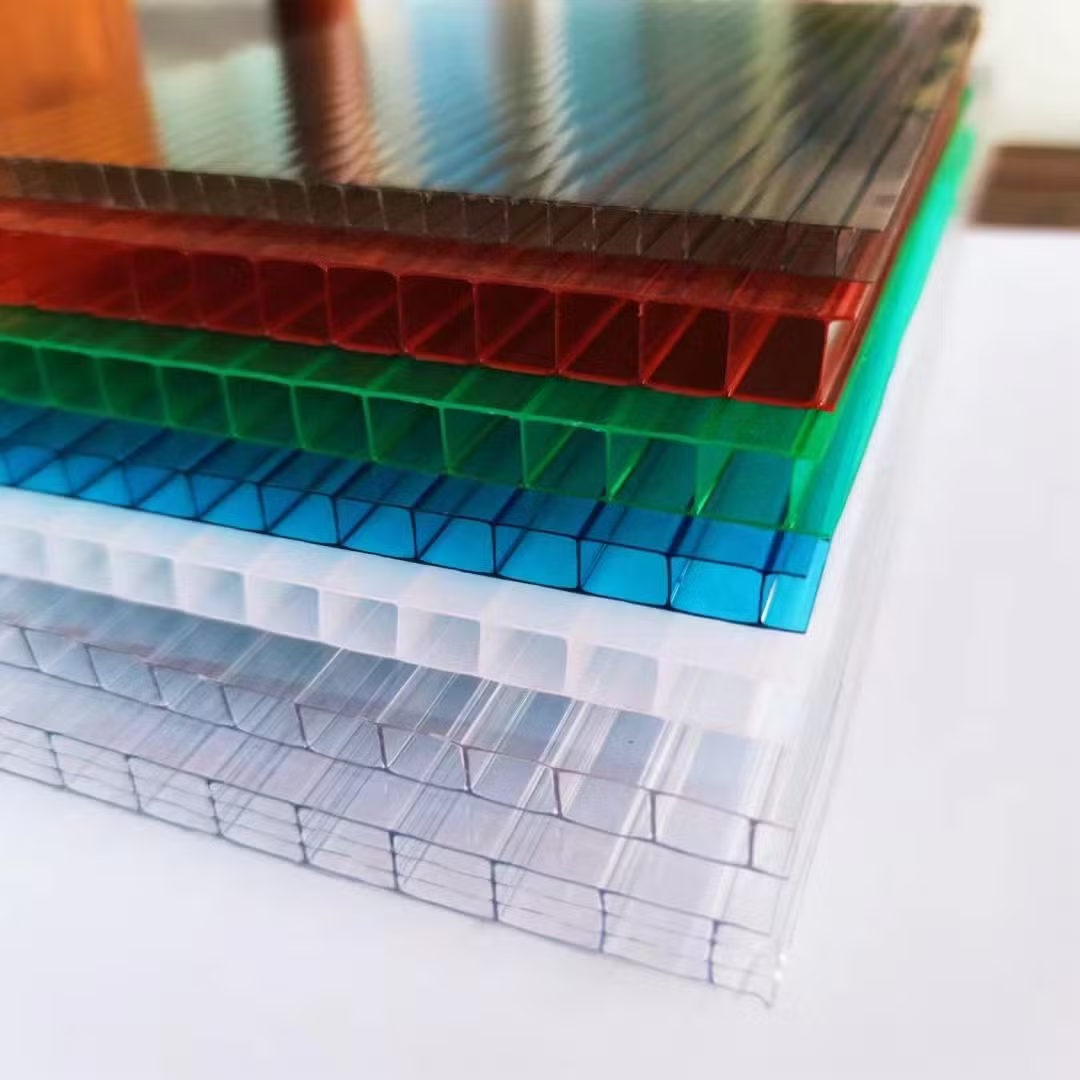

Types of Polycarbonates Available in Kenya

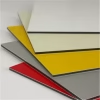

Egyptian Polycarbonates

Egyptian polycarbonates are known for their:

- Consistent quality control meeting international standards

- Competitive pricing compared to European imports

- Durability in Kenya’s tropical climate conditions

- Wide range of thicknesses and formulations

These polycarbonates are particularly popular in Kenya’s construction industry for roofing applications and in the manufacturing sector for protective equipment.

Chinese Polycarbonates

Chinese polycarbonates available in Kenya offer:

- Cost-effectiveness: Generally more affordable than other imports

- Variety: Extensive range of grades including UV-resistant and flame-retardant options

- Volume availability: Suitable for large-scale projects

- Innovative formulations: Including blends with ABS and glass fiber reinforcement

However, quality can vary significantly between manufacturers, making it crucial to work with reputable suppliers who vet their sources carefully.

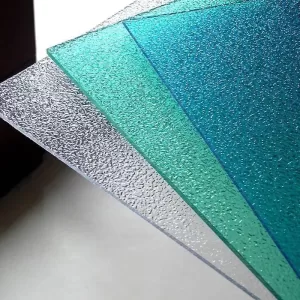

Embossed Polycarbonates

Embossed polycarbonates feature textured surfaces that provide both aesthetic appeal and functional benefits:

- Light diffusion: Reduces glare while maintaining brightness

- Privacy: Obscures views while allowing light transmission

- Anti-slip properties: Important for flooring and walkway applications

- Decorative applications: Used in interior design and signage

These specialized polycarbonates are increasingly popular in Kenya’s architectural projects and retail spaces.

Key Properties and Advantages of Polycarbonates

Polycarbonates offer an exceptional combination of properties that make them superior to many other transparent materials:

Table 1: Key Properties of Polycarbonates Compared to Other Materials

| Property | Polycarbonate | Glass | Acrylic | PVC |

|---|---|---|---|---|

| Impact Resistance | Extremely high | Low | Moderate | Moderate |

| Light Transmission | Up to 90% | 90-92% | 92% | 80-90% |

| Weight | Light (half of glass) | Heavy | Light | Light |

| UV Resistance | Excellent (with coatings) | Excellent | Good | Varies |

| Heat Resistance | Up to 135°C | High | 70-90°C | 60-80°C |

| Flame Resistance | Self-extinguishing | Non-flammable | Burns slowly | Varies |

| Workability | Easy to cut/form | Difficult | Easy | Easy |

The unique advantages of polycarbonates include:

- Exceptional durability: Polycarbonate is virtually unbreakable, making it ideal for security applications and areas prone to impact.

- Thermal stability: Maintains properties across a wide temperature range (-40°C to 135°C).

- Design flexibility: Can be molded into complex shapes while maintaining optical clarity.

- Safety: Breaks into large, dull pieces rather than sharp shards like glass.

- Long-term performance: Resistant to yellowing when properly treated with UV inhibitors.

Applications of Polycarbonates in Kenya

Construction Industry (25% of global polycarbonate use 5)

- Roofing systems: Skylights, canopy roofs, and greenhouse coverings

- Glazing applications: Windows, partitions, and noise barriers

- Security installations: Bullet-resistant and vandal-proof barriers

- Decorative elements: Embossed panels for interior design

The construction sector in Kenya is increasingly adopting polycarbonates for their durability and energy efficiency benefits.

Electrical & Electronics (35% of global demand)

- Device housings: For smartphones, tablets, and appliances

- LED light covers: Diffusers and protective covers

- Electrical components: Connectors and insulating parts

- Optical media: Though declining, still used in some applications

Kenya’s growing tech sector creates significant demand for high-quality polycarbonates in electronics manufacturing.

Automotive Industry (16% of polycarbonate consumption)

- Headlamp lenses: Withstand impacts and maintain clarity

- Instrument panels: Durable and aesthetically pleasing

- Window glazing: Particularly in electric vehicles

- Interior trim components

As Kenya’s automotive market expands, especially with increased interest in electric vehicles, polycarbonate usage is expected to grow significantly.

Other Notable Applications

- Medical devices: Sterilizable equipment and transparent enclosures

- Food service: Display cases and processing equipment windows

- Signage and displays: PALCLEAR® alternatives for indoor use

- Security documents: Polycarbonate layers in IDs and passports

Market Trends in Kenya’s Polycarbonate Sector

The Kenyan polycarbonate market reflects several global trends while maintaining unique local characteristics:

- Growing preference for locally available stocks: With Egyptian and Chinese imports becoming more reliable, businesses are shifting from European/American suppliers to reduce lead times and costs.

- Increased quality awareness: As applications become more demanding, Kenyan buyers are becoming more sophisticated in their material specifications.

- Sustainability focus: Recycled and recyclable polycarbonate options are gaining attention among environmentally conscious businesses.

- Customization demand: Embossed and colored polycarbonates are seeing increased use in architectural and design applications.

- Electric vehicle impact: As global automakers invest in EV technologies, Kenya’s automotive aftermarket will likely see more polycarbonate components 5.

Technical Comparison: Egyptian vs. Chinese vs. Embossed Polycarbonates

Table 2: Detailed Comparison of Polycarbonate Types Available in Kenya

| Parameter | Egyptian Polycarbonates | Chinese Polycarbonates | Embossed Polycarbonates |

|---|---|---|---|

| Price Range | Mid-range | Most competitive | Premium |

| UV Stability | Excellent with coatings | Varies by manufacturer | Typically high |

| Surface Finish | Smooth glossy | Smooth glossy | Textured patterns |

| Light Transmission | 88-90% | 85-90% | 50-85% depending on pattern |

| Impact Strength | Very high | High to very high | High (slightly reduced by texturing) |

| Common Thicknesses | 1mm-12mm | 0.5mm-15mm | 2mm-10mm |

| Color Options | Clear, tinted | Extensive range | Typically clear or tinted |

| Thermoformability | Excellent | Good to excellent | Requires specialized techniques |

| Typical Lead Times | 4-6 weeks | 8-12 weeks (sea freight) | 4-8 weeks |

| Best For | Structural applications | Cost-sensitive projects | Aesthetic applications |

Frequently Asked Questions (FAQs) About Polycarbonates in Kenya

Q1: How does polycarbonate compare to acrylic in Kenyan climate conditions?

Polycarbonate outperforms acrylic in several ways relevant to Kenya:

- 250 times more impact-resistant

- Better heat resistance (important in hot regions)

- More flexible, making it better for high-wind areas

- Superior UV resistance when properly coated

Q2: Can polycarbonate be used for secure applications like ID documents?

Yes, polycarbonate is the material of choice for high-security ID documents like passports and national ID cards. Technologies like Color Laser Shield embed photos and data within the polycarbonate layers, making tampering extremely difficult 6.

Q3: What maintenance do polycarbonate roofs require in Kenya?

- Regular cleaning with mild soap and water

- Avoid abrasive cleaners that could scratch surfaces

- Inspect seals and fittings annually

- Remove debris that could cause “hot spots”

Q4: How long do polycarbonate products typically last in Kenya’s UV conditions?

With proper UV-protective coatings, polycarbonate can maintain its properties for:

- 10+ years in roofing applications

- 5-7 years in constantly sun-exposed installations

- Longer in indoor or protected applications

Q5: Are there fire safety concerns with polycarbonate?

Polycarbonate has inherent flame-retardant properties:

- UL94 V-0 rating (self-extinguishing)

- Low smoke generation compared to many plastics

- Meets most building code requirements when properly installed

Q6: Can polycarbonate be recycled in Kenya?

While recycling infrastructure is still developing:

- Polycarbonate is technically recyclable

- Some local processors accept clean production scrap

- International markets exist for recycled polycarbonate

- Reuse in lower-grade applications is possible

Selecting the Right Polycarbonate for Your Kenyan Project

When choosing between Egyptian, Chinese, and embossed polycarbonates, consider these factors:

- Application requirements:

- Structural needs (impact resistance, load-bearing)

- Optical clarity requirements

- Exposure conditions (UV, chemicals, temperature)

- Budget constraints:

- Initial material costs

- Installation expenses

- Long-term maintenance considerations

- Aesthetic preferences:

- Transparency/translucency needs

- Surface finish requirements

- Color matching

- Supply chain factors:

- Availability of specific grades/sizes

- Lead times for special orders

- Local technical support

For most commercial and industrial applications in Kenya, Egyptian polycarbonates offer an excellent balance of quality and value. Chinese imports can provide cost savings for large-volume, less critical applications. Embossed polycarbonates serve specialized needs where light diffusion or decorative effects are desired.

Installation and Handling Tips for Polycarbonates

Proper handling ensures optimal performance of your polycarbonate materials:

- Storage:

- Keep in original packaging until use

- Store flat in a dry, shaded area

- Avoid contact with solvents or chemicals

- Cutting and Fabrication:

- Use fine-tooth blades for clean cuts

- Support sheets properly to prevent vibration

- Remove protective film only after installation

- Installation:

- Allow for thermal expansion (about 3mm per meter)

- Use proper sealing techniques to prevent water ingress

- Follow manufacturer’s recommendations for fasteners

- Cleaning:

- Use soft cloths or sponges

- Mild detergent solutions are typically sufficient

- Avoid abrasive cleaners or tools

Future Outlook for Polycarbonates in Kenya

The Kenyan polycarbonate market is poised for significant growth in several areas:

- Electric Vehicle Components:

As global EV adoption grows, Kenya’s automotive sector will see increased use of polycarbonates in battery casings, body panels, and charging infrastructure. - Smart Building Technologies:

Polycarbonates will play a role in integrated photovoltaic systems and intelligent glazing solutions. - Enhanced Security Features:

Building on technologies like Color Laser Shield, we’ll see more advanced anti-counterfeiting and security applications. - Sustainable Formulations:

Bio-based and recycled-content polycarbonates will gain market share as environmental regulations tighten. - Medical Applications:

Kenya’s growing healthcare sector will utilize more polycarbonate in equipment and facilities.

Conclusion

Polycarbonates have become indispensable materials across multiple industries in Kenya, offering unparalleled combinations of strength, clarity, and durability. Whether you’re considering Egyptian polycarbonates for their balanced performance, Chinese imports for cost-effective solutions, or embossed varieties for specialized applications, understanding the differences ensures optimal project outcomes.

As Kenya’s construction, manufacturing, and technology sectors continue to grow, polycarbonates will play an increasingly vital role. By selecting the right type for each application and following proper handling and installation practices, Kenyan businesses can maximize the value of these versatile materials.

For those looking to source high-quality polycarbonates in Kenya, working with established suppliers who understand both the global market and local requirements is essential. With proper selection and application, polycarbonate solutions can deliver long-term performance and value across countless uses in the Kenyan context.

Leave a reply