How to Clean and Maintain Perspex Sheets for Maximum Clarity

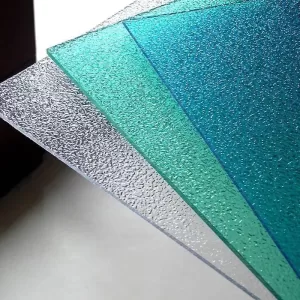

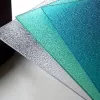

Perspex sheets have become one of the most widely used materials in Kenya for glazing, signage, protective barriers, roofing elements, displays, and interior décor. Their lightweight nature, impact resistance, and glass-like clarity make them a preferred alternative to traditional glass—especially in high-risk or high-traffic environments. From modern offices to schools, retail shops, hospitals, and residential spaces, Perspex (acrylic) sheets continue to offer unmatched versatility and performance.

However, to enjoy crystal-clear transparency and long-term durability, Perspex sheets require correct cleaning, routine maintenance, and proper handling. Many users assume Perspex behaves like glass, yet acrylic sheets require a very different care approach. Using the wrong cloth, chemicals, or techniques can cause scratches, cloudiness, and long-term damage that affects their appearance and performance.

This comprehensive guide explains everything you need to know about cleaning and maintaining Perspex sheets for maximum clarity and longevity. Whether you are buying new Perspex panels from a supplier such as BHD or maintaining existing installations, this guide will equip you with the correct best practices. If you’re also exploring alternative materials like polycarbonate roofing sheets, you can learn more through BHD’s product selection at Polycarbonate Roofing Sheets.

Understanding Perspex Sheets and Why Proper Cleaning Matters

Perspex is a brand name for high-quality acrylic sheets. These sheets are known for their exceptional clarity, high impact resistance, and UV stability. They are often used in commercial and industrial settings as a lightweight yet durable option for glass.

Despite their strength, Perspex is still prone to surface scratching and chemical damage if handled incorrectly. Poor cleaning practices can lead to:

-

Swirl marks and scratches

-

Cloudiness and permanently dull surfaces

-

Cracks caused by chemical reactions

-

Yellowing over time due to improper care

-

Loss of transparency and shine

Because of these risks, knowing the right techniques and avoiding common mistakes ensures your Perspex sheets look new and clear for years. For detailed material insights, BHD has helpful resources on products like Premium Perspex Sheets in Nairobi and Solid Polycarbonate Sheets for customers who compare acrylic vs. polycarbonate applications.

Common Mistakes When Cleaning Perspex Sheets

Before discussing the correct process, it’s important to understand what NOT to do. Many people ruin perfectly good Perspex by using incorrect cleaning materials.

Avoid These Common Mistakes:

-

Using rough or abrasive cloths

Items like kitchen towels, t-shirts, and paper towels may seem harmless but easily scratch acrylic. -

Using strong or corrosive chemicals

Products like acetone, window cleaners containing ammonia, turpentine, or kerosene cause cracking and clouding. -

Dry wiping dusty Perspex

Dust contains tiny abrasive particles. Wiping without wetting causes micro-scratches. -

Using scouring pads or rough sponges

These leave deep scratches that cannot be polished out easily. -

Applying too much pressure

Perspex scratches more easily than glass, so gentle pressure is essential. -

Placing heavy items on top during cleaning

Any friction or dragging creates deep marks.

For complete guidance on handling and maintaining different construction materials, BHD provides helpful articles and product guidelines—see their Frequently Asked Questions page.

Tools and Materials You Need to Clean Perspex Sheets Properly

To preserve clarity and prevent scratching, use only recommended cleaning tools.

Approved Cleaning Materials:

-

Microfibre cloth (soft, non-abrasive)

-

Clean, lukewarm water

-

Soft dish soap (non-scented)

-

Plastic cleaner or acrylic-safe cleaning solution

-

Air blower or soft brush for initial dust removal

-

Spray bottle (optional)

-

Soft drying cloth

If you choose to polish your Perspex, you may also need:

-

Acrylic polish

-

Buffing pad (very soft)

Avoid DIY polishing creams that contain grit or solvents—they can permanently scratch acrylic.

How to Clean Perspex Sheets for Maximum Clarity (Step-by-Step Guide)

Below is the most effective and safest method for cleaning Perspex sheets while maintaining their clarity.

Step 1: Remove Loose Dust and Debris

Never start by rubbing the surface. Use:

-

A soft air blower

-

A feather duster

-

A clean, ultra-soft brush

This eliminates abrasive particles that would scratch the surface if rubbed in.

Step 2: Prepare a Mild Soap Solution

Mix a few drops of mild dish soap with lukewarm water.

Avoid:

-

Hot water (causes warping)

-

Strong detergents

-

Soaps with artificial colouring or fragrances

The goal is to use the gentlest solution possible.

Step 3: Wash the Sheet Gently

Dip a microfibre cloth in the soapy water and wipe gently using straight motions, not circular rubbing.

Circular motion encourages swirl scratches.

Step 4: Rinse with Clean Water

Rinse thoroughly with clean, lukewarm water to remove any remaining soap residue.

Soap left behind can cause haziness or streaking, especially under sunlight.

Step 5: Dry with a Soft Microfibre Cloth

Gently pat the surface dry. Do not use paper towels or abrasive fabrics.

Allow the Perspex to air dry fully before handling or reinstalling.

Step 6: Apply Acrylic Polish (Optional but Recommended)

Acrylic-safe polish restores shine and removes fine scratches.

Use sparingly and buff lightly.

If you need guidance on selecting safe finishing materials for interior or exterior use, explore BHD’s WPC Wall Panels in Kenya or Marble Boards in Kenya for compatible décor products.

How to Remove Scratches from Perspex Sheets

Even with proper care, scratches may still occur. The following techniques can help restore clarity.

1. For Light Scratches

Use an acrylic polish or specialised scratch remover.

Apply small amounts and buff slowly.

Avoid circular motion—use straight, overlapping strokes.

2. For Deeper Scratches

You may need:

-

Wet sanding (very fine sandpaper such as 2000–3000 grit)

-

Followed by acrylic polishing

Important:

Wet sanding must be done carefully. Too much pressure will distort the sheet. If unsure, contact a Perspex expert or the supplier.

3. For Severe Damage

Deep gashes may not polish out and could require replacement.

You can explore replacement options such as Premium Perspex Sheets Nairobi or alternative durable glazing solutions like Polycarbonate Sheets in Kenya.

Preventive Maintenance Tips for Long-Lasting Clarity

Perspex is extremely durable when maintained correctly. These best practices prolong service life and reduce the need for polishing or replacement.

1. Protect Against UV Damage

Perspex sheets are UV-stable, but long-term exposure without cleaning can cause gradual yellowing.

Clean regularly and apply recommended UV-safe polishes if installed outdoors.

2. Avoid Sharp Objects

Keep tools, jewellery, and sharp hardware away from the surface.

If you’re installing Perspex alongside other construction materials like MS Flat Bars, Black Pipes, or Rectangular Hollow Sections (RHS), ensure proper spacing to reduce accidental abrasions.

3. Do Not Use Ammonia-Based Cleaners

Products like common glass cleaners cause:

-

Cracking

-

Haze

-

Brittleness

This is one of the leading causes of acrylic failure.

4. Regular Light Cleaning

Frequent gentle cleaning is safer than occasional deep cleaning.

It prevents buildup of dirt that needs more forceful removal.

5. Use Protective Films During Storage

If storing Perspex sheets:

-

Keep the protective film on

-

Store upright

-

Avoid moisture

For contractors handling multiple building materials such as TMT Bars or Square Hollow Sections (SHS), always store Perspex separately to avoid accidental scratching.

Where Perspex Sheets Are Commonly Used and How Maintenance Differs

Different installations require different levels of maintenance. Below is how to care for Perspex based on its application.

1. Perspex Windows and Glazing

Clean gently every 1–2 weeks.

Outdoor installations may require monthly polishing for UV resistance.

2. Perspex Counter Barriers (Shops, Banks, Offices)

Because these surfaces encounter fingerprints and dust frequently:

-

Clean daily or after every shift

-

Use soft cloths only

3. Perspex Signage and Displays

Avoid harsh solvents used in signage printing.

Clean with water and mild soap only.

4. Perspex Skylights and Roofing Elements

For raised installations:

-

Use a safe ladder (see Buy Quality Ladders in Kenya)

-

Use long-handle cleaning tools to avoid overly leaning on sheets

Skylights require cleaning at least four times a year to avoid cloudiness.

To explore safer roofing options, consider Best Polycarbonates in Kenya.

When to Replace Perspex Sheets

Signs that your Perspex sheet needs replacement:

-

Permanent yellowing

-

Deep cracks

-

Cloudiness that doesn’t polish off

-

Structural damage

-

Warping from heat exposure

When upgrading installations, BHD offers multiple alternatives through their Construction Materials in Kenya collection.

Why Buy Perspex Sheets from BHD?

BHD is one of Kenya’s most trusted suppliers of Perspex, polycarbonate, and construction materials. When you buy Perspex sheets from BHD, you benefit from:

1. High-Quality, Crystal-Clear Perspex

Their acrylic sheets undergo strict quality checks to ensure:

-

Excellent clarity

-

UV resistance

-

Strong impact performance

-

Smooth finishing

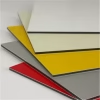

2. Wide Variety of Materials

Whether you need Perspex, polycarbonate, alucobond, or steel materials like MS Angle and Chequered Plates, BHD stocks everything under one roof.

3. Expert Guidance and Support

BHD’s team helps you choose the right thickness, size, and type of Perspex sheet based on your project needs.

Their About Us Page offers more insights into their experience in the materials industry.

4. Reliable Deliveries Countrywide

BHD offers same-day delivery in Nairobi and next-day deliveries across Kenya.

For assistance, visit the Contact Us Page.

Final Thoughts

Perspex sheets offer unmatched clarity, strength, and versatility for both commercial and residential applications. With proper cleaning and maintenance, they can retain their transparency and shine for decades. The key is using the correct materials, avoiding harsh chemicals, and following a gentle cleaning routine.

If you’re planning to replace or purchase new Perspex sheets, or comparing alternatives like polycarbonate or alucobond, BHD provides a full range of quality construction solutions.

Visit www.bhd.co.ke to explore Perspex sheets, polycarbonates, structural steel, and more building materials.

Strong Call to Action

For high-quality Perspex sheets, expert support, and reliable delivery:

Visit BHD’s Nairobi branch

Check pricing at www.bhd.co.ke

Request expert advice on choosing the right materials for your project.

COUNTRYWIDE DELIVERIES AVAILABLE

Same-day delivery within Nairobi

Next-day delivery to other parts of the country

We supply all types of MS Flat Bars, Polycarbonate, and Perspex Sheets — delivered right to your location.

Contact Us

Burhani Hardware Dealers

Email: burhanihardwaredealers [at] yahoo.com

Call/WhatsApp: +254 731 217 462 | +254 704 606 131

Visit: BHD, Industrial Area, Funzi Road, Nairobi

We deliver to: Nairobi, Nakuru, Kisumu, Mombasa, Malindi, Eldoret, Kisii, Migori, Moyale, Lodwar, Marsabit, Maralal, Kapenguria, Kitale, Isiolo, Rumuruti, Webuye, Bungoma, Malaba, Busia, Mumias, Kakamega, Siaya, Luanda, Bondo, Mbita, Homa Bay, Rongo, Sotik, Bomet, Narok, Kericho, Kapsabet, Gilgil, Nyahururu, Nanyuki, Meru, Thika, Maua, Chuka, Limuru, Naivasha, Kitui, Mutomo, Kajiado, Emali, Kitengela, Oloitoktok, Garissa, Mwingi, Kibwezi, Mtito Andei, Voi, Diani, Lamu, Garsen, Kilifi, Mtwapa, Mariakani, Kikuyu, Ngong, Karen, Athi River — and many more.

Leave a reply