Perspex vs Glass: Which Material Is Best for Your Application?

When it comes to choosing materials for windows, displays, signage, or protective barriers, the decision often comes down to Perspex (acrylic sheets) and glass. Both materials have unique properties, advantages, and limitations that influence their suitability for different applications. This comprehensive guide will help you make an informed choice for your next project.

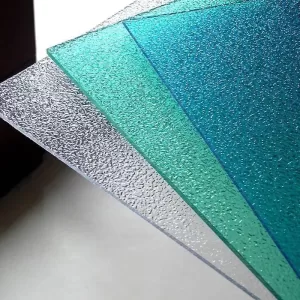

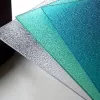

What is Perspex?

Perspex, also known as acrylic sheets, is a lightweight, transparent thermoplastic often used as an alternative to glass. It’s widely appreciated for its clarity, durability, and ease of fabrication. Perspex can be cut, drilled, and shaped without cracking, making it a versatile choice for many construction, decorative, and industrial applications.

Key Properties of Perspex:

-

Lightweight (approximately half the weight of glass)

-

High impact resistance (up to 10–17 times stronger than glass)

-

Excellent optical clarity (up to 92% light transmission)

-

Easily fabricated and thermoformed

For more options on acrylic sheets, you can check out BHD’s Premium Perspex Sheets in Nairobi.

What is Glass?

Glass is a hard, brittle material made primarily from silica, soda, and lime. It has been used for centuries in construction, windows, and decorative applications due to its rigidity, transparency, and scratch resistance.

Key Properties of Glass:

-

High scratch resistance

-

Excellent clarity and transparency

-

Can be tempered or laminated for added strength

-

Durable and resistant to UV degradation

Glass is the traditional choice for applications requiring rigid, scratch-resistant, and high-clarity surfaces.

Perspex vs Glass: Key Comparisons

1. Weight

Perspex is lighter than glass, which makes it easier to transport and install, especially in large panels or overhead applications. Glass, in contrast, is heavier and may require more robust support structures.

2. Strength & Durability

While glass is hard, it can shatter on impact. Perspex is highly impact-resistant, making it safer in environments where breakage is a concern, such as schools, hospitals, or public spaces.

3. Clarity & Light Transmission

Both Perspex and glass offer excellent clarity. However, Perspex has a slight advantage in optical clarity and can be coated for anti-glare or UV resistance, which protects interiors from fading.

4. Scratch Resistance

Glass is more scratch-resistant than Perspex. Perspex can scratch more easily, but minor scratches can be polished out, whereas glass scratches are usually permanent.

5. Cost

Perspex is generally more affordable than glass for larger panels and specialty shapes. Glass costs can rise significantly for tempered, laminated, or specialty finishes.

6. Fabrication & Installation

Perspex is easier to cut, drill, bend, and shape, offering more flexibility for creative designs. Glass requires specialized tools and skilled labor for shaping and installation.

Applications of Perspex

Perspex is ideal for:

-

Signage and displays – lightweight and easy to shape

-

Protective barriers – impact-resistant screens for offices and banks

-

Furniture and decorative panels – flexible design options

-

Windows in light structures – lightweight alternatives to glass

Explore more about acrylic sheets and related products at BHD’s Solid Polycarbonate Sheets page.

Applications of Glass

Glass is best suited for:

-

Windows and doors – structural rigidity and aesthetics

-

Skylights and partitions – clarity and scratch resistance

-

Shower screens and mirrors – long-lasting durability

-

Tempered or laminated safety applications – high-strength requirements

Choosing Between Perspex and Glass

Your choice depends on your project priorities:

| Feature | Perspex | Glass |

|---|---|---|

| Weight | Lightweight | Heavy |

| Impact Resistance | High | Low (shatters easily) |

| Scratch Resistance | Low | High |

| Cost | Affordable | Expensive (esp. tempered/laminated) |

| Fabrication | Easy to cut & shape | Difficult, specialized tools needed |

| Applications | Signage, barriers, decorative panels | Windows, doors, mirrors, skylights |

Tip: If safety and impact resistance are critical, Perspex is the better choice. If scratch resistance, clarity, and long-term rigidity matter most, glass is preferable.

Conclusion

Both Perspex and glass have their strengths. Perspex offers lightweight, flexible, and impact-resistant solutions, making it ideal for creative or high-safety applications. Glass provides scratch resistance, rigidity, and classic aesthetics, making it a reliable choice for traditional construction and long-lasting installations.

For Kenyan contractors, builders, and homeowners looking for high-quality materials, BHD offers a wide range of Perspex sheets to suit various applications. Check out BHD’s Premium Perspex Sheets in Nairobi to explore sizes, colors, and thickness options.

Contact BHD today at +254 731 217 462 or visit the Contact Us page for expert advice and nationwide delivery.

Leave a reply