Across Kenya’s diverse agricultural zones—from the cool highlands of Nyandarua and Meru to the warmer regions of Machakos, Kajiado, and parts of Rift Valley—greenhouse farming has become a key driver of food security and agribusiness growth. As farmers move away from traditional polythene covers, polycarbonate sheets for Kenyan greenhouses are increasingly preferred for their superior insulation, UV protection, durability, and measurable impact on crop performance.

This guide breaks down how polycarbonate sheets perform in Kenyan greenhouse conditions, focusing on thermal insulation, UV control, and crop yield outcomes, so farmers, agronomists, and agribusiness investors can make informed decisions.

Why Polycarbonate Sheets Are Gaining Popularity in Kenyan Greenhouses

Greenhouse success depends heavily on controlling light, temperature, and humidity. Polycarbonate sheets offer a long-term solution that addresses common challenges faced by Kenyan farmers, including heat stress, inconsistent rainfall, and material degradation.

Compared to polythene and glass, polycarbonate sheets are:

-

Stronger and more impact-resistant

-

Better at retaining heat during cold nights

-

UV-stabilized for long outdoor lifespan

-

More cost-effective over time due to durability

These advantages make them ideal for both small-scale farmers and commercial greenhouse operations.

Insulation Performance of Polycarbonate Sheets in Kenya

Thermal Regulation in Different Regions

Kenya experiences wide temperature variations depending on altitude and season. Polycarbonate sheets—especially twinwall and multiwall variants—trap air between layers, acting as an insulating barrier.

This insulation helps:

-

Retain warmth during cold nights in highland areas

-

Reduce heat loss during rainy seasons

-

Stabilize internal temperatures, reducing crop stress

Stable temperatures are critical for crops like tomatoes, capsicum, cucumbers, strawberries, and flowers, which are highly sensitive to sudden temperature drops.

Day–Night Temperature Balance

In many Kenyan regions, daytime heat is intense while nights can be significantly cooler. Poor insulation causes:

-

Slowed plant metabolism

-

Flower drop

-

Reduced fruit set

Polycarbonate sheets moderate these fluctuations, supporting consistent plant growth cycles and improving overall productivity.

UV Protection: Protecting Crops While Maximizing Light

UV Stabilization and Light Diffusion

High-quality polycarbonate sheets come with UV-protective coatings that block harmful ultraviolet radiation while allowing optimal visible light transmission.

Benefits include:

-

Reduced leaf burn and plant stress

-

Prevention of plastic degradation

-

Longer material lifespan (often 10–15 years)

Light-diffusing polycarbonate also spreads sunlight evenly across crops, preventing hotspots and improving uniform growth—especially important for leafy greens and nursery seedlings.

Crop-Specific Light Benefits

Different crops respond differently to light intensity:

-

Vegetables benefit from balanced diffusion to avoid heat stress

-

Flowers gain better color consistency

-

Seedlings experience stronger early-stage development

By selecting the right polycarbonate profile and tint, farmers can tailor light conditions to their crop type.

Impact on Crop Performance and Yield

Improved Growth Rates

With controlled temperature and optimized light transmission, crops grown under polycarbonate greenhouses often show:

-

Faster vegetative growth

-

Higher flowering rates

-

Improved fruit quality

This translates directly into higher yields per square meter.

Reduced Pest and Disease Pressure

Stable greenhouse environments reduce:

-

Condensation-related fungal diseases

-

Stress-induced pest susceptibility

While polycarbonate itself is not a pest control solution, the controlled climate it enables supports healthier plants and lowers crop losses.

Consistent Production Cycles

For commercial farmers supplying urban markets, consistency matters. Polycarbonate greenhouses support:

-

Year-round production

-

Predictable harvest schedules

-

Better planning for contracts and exports

This reliability is a major advantage for agribusiness profitability.

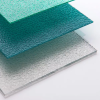

Choosing the Right Polycarbonate Sheets for Greenhouses in Kenya

Sheet Type

-

Twinwall polycarbonate – Best balance of insulation and light transmission

-

Multiwall polycarbonate – Superior insulation for colder regions

-

Solid polycarbonate – High clarity but less insulation (better for nurseries)

Thickness Recommendations

For Kenyan greenhouse applications:

-

4mm–6mm: Small-scale or warm regions

-

8mm–10mm: Commercial greenhouses and highland zones

-

12mm+: Cold-prone areas or export-grade facilities

Thicker sheets cost more initially but reduce heating losses and replacement costs.

Ventilation Compatibility

Insulation must work alongside ventilation. Polycarbonate sheets are compatible with:

-

Roof vents

-

Side roll-up systems

-

Forced ventilation fans

Balanced airflow prevents overheating while preserving insulation benefits.

Cost vs Long-Term Value for Kenyan Farmers

Upfront Cost Considerations

Polycarbonate sheets cost more than polythene initially, but:

-

They last significantly longer

-

Require fewer replacements

-

Reduce temperature-related crop losses

Return on Investment (ROI)

Over multiple seasons, farmers benefit from:

-

Increased yields

-

Reduced maintenance costs

-

Stable crop quality

-

Lower downtime due to material failure

Most commercial growers recover the cost difference within a few production cycles.

Installation Considerations for Agricultural Use

Proper installation is essential:

-

Allow for thermal expansion

-

Use UV side correctly (marked by manufacturer)

-

Ensure tight but flexible fixings

-

Maintain adequate roof slope for drainage

Poor installation reduces insulation effectiveness and material lifespan.

Sustainability and Environmental Benefits

Polycarbonate sheets contribute to sustainable agriculture by:

-

Reducing plastic waste through long lifespan

-

Improving energy efficiency

-

Supporting water-efficient farming systems

For climate-smart agriculture initiatives in Kenya, polycarbonate greenhouses align well with long-term sustainability goals.

Final Thoughts

Polycarbonate sheets for Kenyan greenhouses offer a powerful combination of insulation, UV protection, and improved crop performance. For farmers looking to move beyond short-term solutions and invest in reliable, high-yield greenhouse systems, polycarbonate is one of the most effective materials available today.

When matched with the right thickness, profile, and installation quality, polycarbonate greenhouses help Kenyan farmers grow more, waste less, and earn consistently—season after season.

Leave a reply