Protecting Steel from Rust: Best Practices for Kenyan Conditions

Steel is one of the most widely used materials in construction, fabrication, and industrial applications in Kenya. From MS flat bars to angles, channels, and plates, steel provides strength, durability, and versatility. However, one of its primary challenges is rust and corrosion, especially in Kenya’s diverse climates, ranging from humid coastal regions to inland areas with seasonal rainfall.

Rust can weaken steel, reduce its load-bearing capacity, and shorten the lifespan of construction projects. Protecting steel from rust is therefore essential for homeowners, contractors, and industrial operators who want to ensure long-term durability and performance. In this article, we explore practical methods, preventive measures, and best practices to safeguard steel under Kenyan conditions.

Understanding Rust and Corrosion in Steel

Rust is the reddish-brown flaky layer that forms when iron or mild steel reacts with oxygen and moisture. Corrosion, on the other hand, is a broader term encompassing all forms of chemical or electrochemical degradation of metals.

Factors accelerating steel corrosion in Kenya include:

-

Humidity and coastal salt air (common in Mombasa, Kilifi, Malindi)

-

Rainfall and water exposure (Nairobi, Nakuru, Kisumu regions)

-

Industrial pollutants

-

Soil moisture in foundations and underground installations

Understanding these conditions helps builders choose appropriate protective measures for construction steel like MS flat bars, MS angles, and HR channels.

Best Practices for Protecting Steel from Rust in Kenya

1. Galvanization

Galvanization involves coating steel with a layer of zinc to protect it from rust. This process is highly effective in coastal and humid regions of Kenya. Benefits include:

-

Long-lasting corrosion protection

-

Reduced maintenance requirements

-

Suitability for outdoor structures such as gates, roofing supports, and frameworks

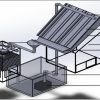

Galvanized steel is ideal for applications like roof frames for polycarbonate sheets, fencing, and industrial constructions.

2. Painting and Coating

Applying high-quality paint or powder coating is another effective way to prevent rust. Coatings act as a physical barrier against moisture and oxygen. Key tips for Kenyan conditions:

-

Use anti-corrosive primers before painting

-

Apply UV-resistant topcoats for sunny areas

-

Regularly inspect and touch up damaged areas

This method works well for interior steel applications, stair railings, gates, and decorative frames.

3. Using Stainless Steel or Alloyed Steel

For highly corrosive environments, such as coastal regions or areas with heavy rainfall, consider stainless steel or alloyed steel. Although more expensive than mild steel, these materials naturally resist corrosion and require minimal maintenance.

BHD stocks high-quality steel options for both structural and decorative purposes, ensuring your investment lasts for decades.

4. Proper Storage and Handling

Steel is vulnerable to rust even before installation. Best practices in storage and handling include:

-

Keep steel off the ground using wooden pallets or racks

-

Store in dry, ventilated areas

-

Cover steel with waterproof tarpaulins during rainy seasons

-

Avoid direct contact with water or soil

Following these steps prevents premature rusting, especially for steel materials stored for construction projects in Nairobi, Kisumu, and Nakuru.

5. Regular Maintenance and Inspection

Even with protective coatings or galvanization, steel requires periodic inspection and maintenance. Regularly check for signs of rust or corrosion:

-

Scratches or damaged coatings

-

Discoloration or surface pitting

-

Rust stains around joints and welds

Early detection allows corrective action, extending the lifespan of steel structures.

6. Cathodic Protection

For large-scale or underground structures, cathodic protection can prevent electrochemical corrosion. This involves using sacrificial anodes or impressed current systems to divert corrosion away from the main steel structure. It is commonly used in industrial plants, pipelines, and marine constructions.

Recommended Steel Products for Rust Protection

At BHD, we provide a range of steel products suitable for corrosion prevention and long-term construction:

-

MS Flat Bars – suitable for indoor and outdoor framing

-

MS Angles – ideal for corner reinforcement in humid environments

-

HR Channels – perfect for roofing and bracing applications

-

TMT Bars – reinforced steel for foundations and heavy-duty structures

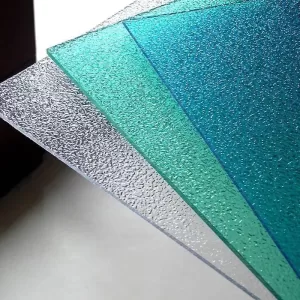

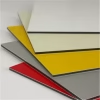

Complementing steel with polycarbonate roofing or Alucobond sheets can further protect steel from direct weather exposure.

Final Thoughts & Call to Action

Protecting steel from rust is essential for maintaining structural integrity, safety, and aesthetics in construction projects across Kenya. By combining galvanization, coatings, proper storage, and regular maintenance, you can significantly extend the lifespan of steel materials like MS flat bars, angles, and channels.

For high-quality, durable steel products and expert advice on rust prevention, BHD.co.ke is your trusted supplier.

Countrywide Deliveries Available

Same-day delivery within Nairobi

Next-day delivery to other parts of Kenya

Contact us: Burhani Hardware Dealers

burhanihardwaredealers [at] yahoo.com

Call/WhatsApp: +254 731 217 462 | +254 704 606 131

Visit: BHD, Industrial Area, Funzi Road, Nairobi

We deliver to Nairobi, Mombasa, Kisumu, Eldoret, Nakuru, Malindi, Kitale, Garissa, Nyeri, Thika, and many more locations nationwide.

Leave a reply