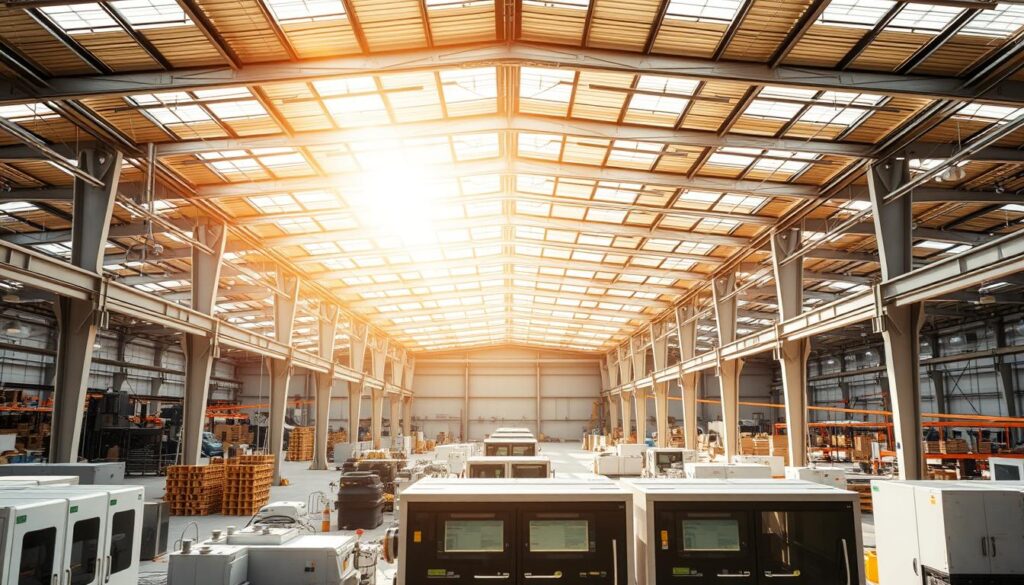

Warehouses in Kenya consume massive amounts of electricity, especially for lighting during daytime operations. One of the most cost-effective upgrades is installing skylight strips, which use natural daylight to reduce reliance on KPLC-powered lighting. Properly implemented, skylight strips can cut your electricity bills by up to 30%, while improving working conditions and reducing carbon footprint.

What Are Skylight Strips?

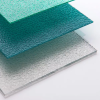

Skylight strips are typically made from polycarbonate sheets or fiberglass reinforced plastic (FRP). They are installed in continuous rows along the roof ridges or slopes. Their transparency allows diffused sunlight to illuminate the warehouse without causing glare or heat buildup.

Materials Available in Kenya:

-

Solid Polycarbonate Sheets – impact-resistant and UV-stabilized

-

Egyptian Hollow Polycarbonate Sheets – lightweight, cost-effective, excellent insulation

Installation Tip: Ensure the strips are aligned with warehouse aisles to optimize daylight penetration while avoiding direct sun glare.

How Skylight Strips Reduce KPLC Bills

By using natural daylight to replace electric lighting, skylight strips can reduce energy consumption by 25–30% in Kenyan warehouses. This translates to significant savings on KPLC bills, especially in high-use facilities.

Electric lighting accounts for a large portion of warehouse energy usage. During daytime, skylight strips:

-

Reduce the need for overhead fluorescent or LED lighting

-

Improve lighting quality, lowering eye strain for workers

-

Complement energy audits for maximum efficiency

Local Context: In Nairobi, warehouses often operate 10–12 hours/day. Installing skylight strips can reduce lighting-related energy costs by ~KSh 15,000–25,000/month for medium-sized warehouses. Coastal warehouses in Mombasa benefit from high natural light intensity but must use UV-stabilized panels to avoid degradation.

Technical Specifications for Skylight Strips

Kenyan warehouses should use polycarbonate or FRP strips meeting KEBS standards (KS 02-17) for durability, UV resistance, and structural integrity under local wind and rain conditions.

| Material Type | Thickness | Light Transmission | Panel Width | Lifespan | KEBS Standard |

|---|---|---|---|---|---|

| Solid Polycarbonate | 4–16 mm | 80–90% | 600–1200 mm | 10–15 yrs | KS 02-17 |

| Egyptian Hollow Polycarbonate | 10 mm | 65–75% | 980 mm | 8–12 yrs | KS 02-17 |

| FRP Sheet | 2–5 mm | 60–70% | 1000 mm | 7–10 yrs | KS 02-17 |

Note: Use panels with UV-stabilization in high-sun areas like Mombasa and Malindi to avoid yellowing.

Choosing the Right Skylight Strip for Kenyan Warehouses

Select panels based on durability, light transmission, and local climate. Solid polycarbonate is ideal for high-impact, long-lasting installations, while hollow polycarbonate offers insulation and cost savings.

-

High-Humidity Areas (Mombasa, Malindi): Use UV-stabilized, anti-condensation sheets

-

High-Altitude Areas (Nairobi, Nakuru): Standard polycarbonate provides sufficient daylight

-

Large Warehouses: Continuous skylight strips along ridges improve light distribution

Recommended Products from BHD:

-

Buy Solid Polycarbonate Sheets for long-lasting, high-transparency lighting

-

Explore Egyptian Hollow Polycarbonate Sheets for thermal insulation

Installation and Maintenance Tips

Proper installation and maintenance of skylight strips ensure maximum energy savings and durability. Follow KEBS-aligned installation practices and inspect strips every 6 months for cracks or leaks.

Installation Tips:

-

Align strips with warehouse roof ridges for even light distribution.

-

Seal joints with silicone or EPDM gaskets to prevent water ingress.

-

Ensure structural framing supports the weight and expansion of panels.

Maintenance:

-

Clean strips every 3–6 months to maintain light transmission

-

Inspect for UV damage, cracks, or discoloration

-

Replace damaged panels promptly to avoid energy loss

Calculating Potential Savings on KPLC Bills

By replacing daytime electric lighting with skylight strips, warehouses can save 25–30% on monthly KPLC bills. The exact savings depend on warehouse size, panel type, and lighting usage.

Example Calculation – Nairobi Warehouse (2,000 m²):

-

Average electric lighting cost: KSh 80,000/month

-

Skylight strips reduce artificial lighting by 30%

-

Monthly Savings: ~KSh 24,000

Over a year, this translates to KSh 288,000, effectively paying for the skylight installation within 2–3 years depending on material choice and installation costs.

Delivery & Procurement in Kenya

BHD delivers skylight strips and polycarbonate sheets across Kenya with same-day Nairobi delivery and next-day countrywide. Our technical team provides guidance for optimal selection and installation.

Products Available from BHD:

-

Alucobond Sheets for premium roofing solutions

Delivery Guarantee:

-

Same-day delivery within Nairobi

-

Next-day delivery countrywide to Nakuru, Kisumu, Mombasa, Eldoret, Thika, Meru, Kitengela, Malindi

Discover how installing skylight strips in your warehouse can slash your KPLC electricity bills by up to 30%, improve natural lighting, and boost operational efficiency in Kenya.

Conclusion – Why Skylight Strips Are a Must-Have

Skylight strips are a proven solution to reduce KPLC bills, improve warehouse lighting, and comply with KEBS standards. Choosing the right material and proper installation ensures long-term energy savings in Kenyan conditions.

Investing in skylight strips is one of the simplest energy audit recommendations that deliver measurable results in warehouses of all sizes.

Call to Action

Contact Burhani Hardware Dealers (BHD)

burhanihardwaredealers [at] yahoo.com

Call/WhatsApp: +254 731 217 462 | +254 704 606 131

Visit: BHD, Industrial Area, Funzi Road, Nairobi

Website: https://bhd.co.ke/

Delivery Guarantee:

Same-day delivery within Nairobi.

Next-day delivery countrywide to Nakuru, Kisumu, Mombasa, Eldoret, Thika, Meru, Kitengela, Malindi.

Leave a reply