Installation Tips & Best Practices for Alucobond Panels in Exterior Facades

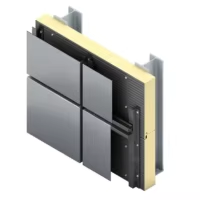

Exterior façades are one of the most visible components of any building, reflecting both structural quality and architectural aesthetics. In Kenya, Alucobond panels have emerged as a top choice for modern façades due to their lightweight design, durability, and sleek appearance. However, to maximize performance and longevity, proper installation is critical.

This guide provides detailed installation tips and best practices for Alucobond panels, helping architects, builders, and contractors in Kenya achieve flawless exterior façades. We’ll also highlight complementary products available from BHD, a trusted supplier of Alucobond and construction materials nationwide.

Understanding Alucobond Panels

Before installing Alucobond, it’s important to understand what makes these panels unique:

-

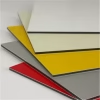

Composition: Two thin aluminum sheets bonded to a polyethylene or fire-retardant core

-

Lightweight yet Strong: Ideal for façades without heavy structural reinforcement

-

Versatile: Can be bent, shaped, or curved for creative designs

-

Durable: Resistant to corrosion, UV exposure, and weather extremes

For high-quality Alucobond panels in Kenya, explore Alucobond Sheets at BHD.

Preparing for Alucobond Panel Installation

Proper preparation ensures a smooth installation and long-lasting façade performance. Key steps include:

1. Assess the Building Structure

-

Verify that the supporting framework is strong and level.

-

Use materials like MS Flat Bars or HR Channels to provide robust mounting support.

-

Check for structural integrity to handle panel weight and environmental stress.

2. Measure and Plan Panel Layout

-

Measure wall surfaces accurately to minimize cutting and wastage.

-

Plan expansion joints to accommodate thermal movement and prevent warping.

-

Mark vertical and horizontal reference lines for precise alignment.

3. Gather Tools and Safety Equipment

-

Power drills, rivet guns, and screwdrivers for fastening

-

Protective gloves, goggles, and scaffolding for safety

-

Sealants, spacers, and trim pieces for weatherproofing

Installation Tips for Alucobond Panels

Correct installation practices ensure performance, aesthetics, and durability.

1. Use the Right Framework

-

Install panels on aluminum or steel frameworks that are leveled and properly anchored.

-

Ensure vertical and horizontal supports are aligned to avoid panel distortion.

2. Handle Panels Carefully

-

Lift panels using gloves and avoid dragging them to prevent scratches.

-

Store panels on flat surfaces before installation.

3. Fastening and Joint Techniques

-

Use screws, rivets, or adhesive bonding depending on project requirements.

-

Leave adequate gaps for thermal expansion (usually 3–5mm per panel edge).

-

Use trims and cover caps to conceal fasteners and protect panel edges.

4. Ensure Proper Sealing

-

Apply weatherproof sealants at joints and corners to prevent water ingress.

-

Use compatible products like PVC Gutters to direct rainwater away from panels.

5. Avoid Excessive Panel Cutting

-

Cut only when necessary, using appropriate tools such as circular saws with carbide-tipped blades.

-

Avoid bending panels beyond manufacturer specifications to prevent damage.

Best Practices for Long-Term Performance

1. Follow Manufacturer Guidelines

-

Always adhere to recommended panel thickness, fastening spacing, and support framework.

-

Verify fire-rated grades for commercial or industrial buildings.

2. Maintain Proper Drainage

-

Ensure façade design allows water to drain freely, preventing corrosion or staining.

-

Incorporate gutters, downpipes, and façade overhangs where applicable.

3. Schedule Routine Inspections

-

Inspect panels periodically for scratches, loose fasteners, or sealant deterioration.

-

Clean panels with mild detergents to maintain appearance; avoid abrasive materials.

4. Combine with Complementary Materials

-

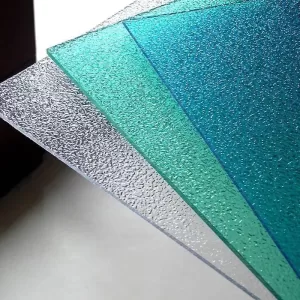

Enhance façade functionality and aesthetics by combining Alucobond with Solid Polycarbonate Sheets or Premium Perspex Sheets.

-

Use WPC Wall Panels for interior transitions or accent features.

Common Installation Mistakes to Avoid

-

Ignoring Expansion Gaps: Can lead to buckling or warping in high-temperature areas.

-

Over-tightening Fasteners: Can deform panels or compromise the finish.

-

Improper Framework Alignment: Results in uneven panel surfaces and misaligned joints.

-

Neglecting Weatherproofing: Can cause water damage, mold, or corrosion over time.

By following best practices, these pitfalls can be avoided, ensuring a flawless façade for years to come.

Why BHD is the Trusted Supplier for Alucobond Panels

BHD provides high-quality Alucobond panels and complementary materials, making installation efficient and reliable:

-

Wide Range of Products: Multiple grades, finishes, and sizes to suit Kenyan building needs.

-

Nationwide Delivery: Same-day delivery within Nairobi, next-day to other regions.

-

Expert Guidance: Recommendations on panel selection, cutting, mounting, and maintenance.

-

Complementary Materials: Access to MS Flat Bars, HR Channels, PVC Gutters, and more.

For product inquiries or advice, visit Contact Us.

Final Thoughts & Call to Action

Proper installation is crucial to unlock the full potential of Alucobond panels in exterior façades. By following preparation, installation tips, and best practices, Kenyan architects, builders, and contractors can achieve durable, attractive, and safe façades.

For premium Alucobond panels, expert installation advice, and nationwide delivery, trust BHD. Explore our Alucobond Sheets or Contact Us to get started.

COUNTRYWIDE DELIVERIES AVAILABLE

Same-day delivery within Nairobi

Next-day delivery across Kenya

Contact us:

Burhani Hardware Dealers

burhanihardwaredealers [at] yahoo.com

+254 731 217 462 | +254 704 606 131

Industrial Area, Funzi Road, Nairobi

We deliver to: Nairobi, Nakuru, Kisumu, Mombasa, Eldoret, Malindi, Kisii, Kitale, Isiolo, Thika, Naivasha, Kitui, Kajiado, Voi, Lamu, Kilifi, Ngong, Karen, Athi River, and many more.

Leave a reply