Choosing the Best Ladders for Construction Sites: Fiberglass vs. Aluminum Safety Standards

Ladders remain one of the most frequently used access tools on Kenyan construction sites, yet they are also among the leading contributors to site injuries. Selecting the wrong ladder material exposes contractors to electrical hazards, structural failure, regulatory penalties, and costly downtime.

In 2026, safety compliance on construction sites is no longer optional. The National Building Code 2024, strengthened occupational safety enforcement, and insurance audits now require contractors to demonstrate that access equipment—including ladders—meets appropriate performance and safety standards.

This guide explains how to choose the best ladders for construction sites, comparing fiberglass and aluminum ladders from a safety, durability, regulatory, and Kenyan climate perspective.

Why Ladder Selection Matters on Kenyan Construction Sites

Ladders are classified as safety-critical equipment under modern construction standards.

Choosing the wrong ladder material increases accident risk and regulatory exposure.

Kenyan construction sites commonly involve:

-

Electrical installations

-

Steel fabrication

-

Concrete works

-

Roofing and façade installation

-

Maintenance at height

Each activity places different demands on ladder material, load capacity, and environmental resistance.

What Are the Main Types of Ladders Used in Construction?

Construction ladders are primarily categorized by material, height rating, and duty class.

Material choice directly affects electrical safety, weight, and durability.

Common ladder types include:

-

Step ladders

-

Extension ladders

-

Platform ladders

-

Fixed access ladders

The two dominant materials in Kenya are aluminum and fiberglass.

What Are Aluminum Ladders and Where Are They Used?

Aluminum ladders are lightweight, corrosion-resistant, and easy to transport.

They are widely used for general construction and non-electrical tasks.

Advantages of Aluminum Ladders

-

Lightweight for easy handling

-

Resistant to rust

-

Cost-effective

-

Suitable for frequent relocation

Common Uses

-

Masonry work

-

Painting

-

Interior finishing

-

General access tasks away from power sources

What Are the Safety Risks of Aluminum Ladders?

Aluminum ladders conduct electricity and pose a serious electrocution risk.

They are unsuitable for electrical or power-adjacent work.

Key risks include:

-

Electrical conductivity

-

Reduced grip in wet conditions

-

Heat absorption in direct sunlight

-

Structural deformation under overload

Under the National Building Code 2024, aluminum ladders are discouraged for tasks near live electrical systems.

What Are Fiberglass Ladders and Why Are They Safer?

Fiberglass ladders are non-conductive and designed for high-risk construction environments.

They offer superior electrical safety and structural stability.

Advantages of Fiberglass Ladders

-

Non-conductive to electricity

-

High load-bearing capacity

-

Better performance in wet conditions

-

Resistant to UV degradation

Fiberglass ladders are preferred on:

-

Electrical installation sites

-

Industrial plants

-

Commercial construction projects

-

Infrastructure developments

How Do Fiberglass Ladders Improve Electrical Safety?

Fiberglass ladders significantly reduce electrocution risk on active sites.

They are classified as electrically insulated access equipment.

This makes them essential for:

-

Power distribution works

-

Elevator installations

-

Data and communication infrastructure

-

Generator and plant maintenance

In Kenya, site safety audits increasingly flag aluminum ladder use near electrical works as non-compliant.

Which Ladder Performs Better Under Kenyan Climate Conditions?

Kenya’s climate affects ladder durability, grip, and long-term safety.

Material choice must account for heat, moisture, and UV exposure.

Coastal Regions (Mombasa, Malindi)

-

High humidity

-

Salt exposure

-

Slip risk

Fiberglass ladders perform better due to:

-

Non-corrosive structure

-

Better traction

-

Stable performance in moisture

Nairobi and Highlands

-

High UV exposure

-

Temperature variation

-

Wind at elevation

Fiberglass ladders resist UV degradation better than aluminum, which can become hot and slippery.

What Load Ratings Should Contractors Consider?

Ladders are rated by duty class, which determines maximum safe load.

Ignoring load ratings is a major cause of ladder failure.

Common Duty Ratings

| Duty Rating | Maximum Load |

|---|---|

| Light Duty | 100 kg |

| Medium Duty | 125 kg |

| Heavy Duty | 150 kg |

| Extra Heavy Duty | 170 kg |

For construction sites, heavy-duty or extra heavy-duty ladders are recommended, especially when workers carry tools or materials.

How Do Safety Standards Apply to Ladders in Kenya?

Construction ladders must comply with safety and performance regulations.

Non-compliant equipment exposes contractors to penalties and liability.

National Building Code 2024

-

Requires safe access systems

-

Emphasizes fall prevention

-

Mandates appropriate equipment selection

Occupational Safety and Health Enforcement

-

Site inspections increasingly scrutinize ladders

-

Unsafe access equipment can trigger stop-work orders

How Does KRA eTIMS Affect Ladder Procurement in 2026?

All construction equipment purchases must be supported by valid eTIMS invoices.

This is required for expense validation and tax compliance.

BHD ensures:

-

Proper invoice documentation

-

Clear product descriptions

-

Audit-ready procurement records

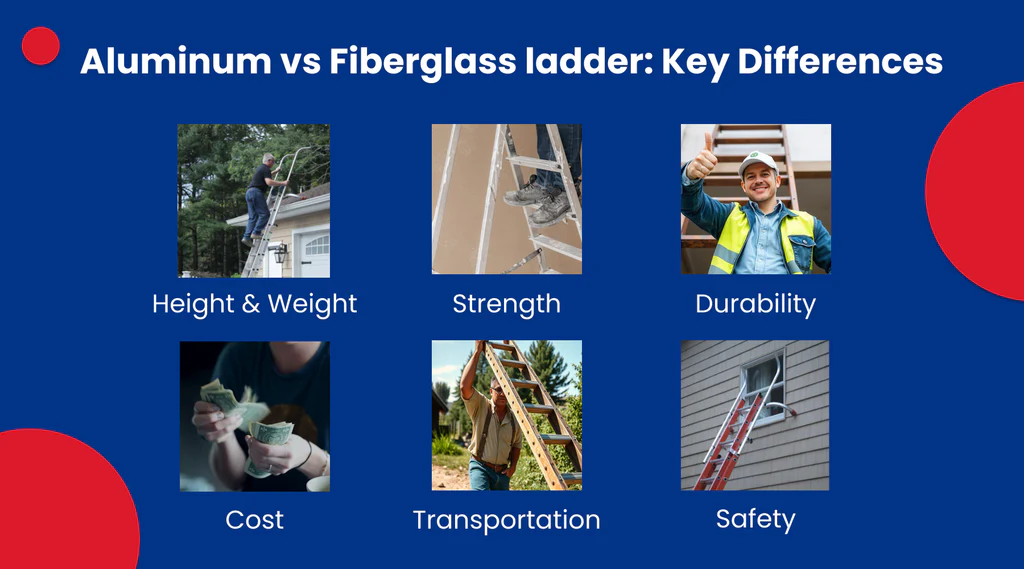

Aluminum vs Fiberglass: Direct Comparison

Material choice should be based on task risk, not just cost.

Fiberglass offers higher safety margins for modern construction sites.

| Feature | Aluminum Ladder | Fiberglass Ladder |

|---|---|---|

| Electrical Conductivity | Conductive | Non-conductive |

| Weight | Lighter | Heavier |

| Cost | Lower | Higher |

| Durability | Moderate | High |

| Climate Resistance | Good | Excellent |

| Safety Rating | Moderate | High |

Leave a reply