Customizing Perspex Sheets: Professional Cutting and Bending Services for Kenyan Fabricators

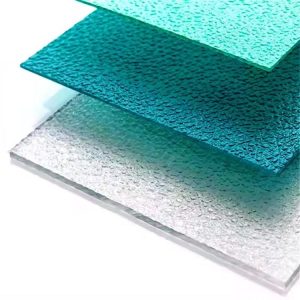

Perspex sheets, also known as acrylic sheets, have become a core material for modern fabrication in Kenya. From architectural glazing and retail displays to industrial machine guards and signage, Perspex offers a rare combination of clarity, strength, and workability.

However, Perspex performance is determined not just by material quality, but by how accurately it is cut, bent, and finished. Poor fabrication leads to cracking, stress marks, warping, and premature failure—issues that cost Kenyan fabricators time, reputation, and money.

Burhani Hardware Dealers (BHD) supports professional fabricators by supplying fabrication-grade Perspex sheets and advising on proper cutting and bending techniques suited to Kenyan climate conditions, regulatory requirements, and site realities.

This guide explains how Perspex sheets are customized, what Kenyan fabricators must consider in 2026, and why professional processing standards matter.

What Are Perspex Sheets and Why Are They Widely Used in Kenya?

Perspex sheets are lightweight, transparent thermoplastic panels known for strength, clarity, and versatility.

They are widely used in Kenya due to their durability, ease of fabrication, and suitability for indoor and outdoor applications.

Perspex is preferred over glass in many applications because it:

-

Is up to 10 times stronger than glass

-

Weighs roughly half as much

-

Offers high optical clarity

-

Can be cut, drilled, bent, and polished

Common Kenyan applications include:

-

Shopfront glazing

-

Signage and branding panels

-

Protective screens and partitions

-

Display cases

-

Skylights and architectural features

Why Customization Is Essential for Kenyan Fabricators

Standard Perspex sheets rarely fit real-world project dimensions without modification.

Professional cutting and bending ensure accuracy, safety, and compliance with design specifications.

Kenyan fabrication projects often involve:

-

Irregular dimensions

-

Retrofitting into existing structures

-

Tight tolerances for commercial interiors

-

Outdoor exposure to sun, heat, and moisture

Customization allows fabricators to:

-

Match architectural drawings precisely

-

Reduce on-site adjustments

-

Maintain clean visual finishes

-

Improve installation efficiency

What Thickness Options Are Available for Perspex Sheets?

Perspex sheets are available in multiple thicknesses to suit structural and aesthetic needs.

Selecting the correct thickness is critical for load-bearing performance and long-term durability.

Common Perspex Thicknesses in Kenya

| Thickness | Typical Use |

|---|---|

| 2 mm – 3 mm | Signage, picture frames, display covers |

| 4 mm – 5 mm | Protective screens, partitions, light-duty glazing |

| 6 mm – 8 mm | Shopfronts, machine guards, balustrades |

| 10 mm – 12 mm | Heavy-duty glazing, structural panels |

BHD advises fabricators to consider:

-

Span length

-

Wind load

-

Mounting method

-

Impact exposure

-

Indoor vs outdoor installation

How Are Perspex Sheets Professionally Cut?

Professional Perspex cutting requires precision tools and controlled techniques to prevent cracking and edge defects.

Improper cutting is the leading cause of material failure in acrylic fabrication.

Common Cutting Methods

CNC Routing

-

High accuracy

-

Clean edges

-

Ideal for complex shapes and repeat jobs

Table Saw Cutting

-

Suitable for straight cuts

-

Requires fine-tooth blades

-

Must control feed rate to prevent melting

Laser Cutting

-

Produces polished edges

-

Best for thin sheets

-

Not recommended for thick structural panels

Key professional practices:

-

Use sharp, acrylic-rated blades

-

Maintain consistent cutting speed

-

Avoid overheating

-

Support sheets fully during cutting

Why Edge Finishing Matters After Cutting

Raw Perspex edges are prone to stress fractures if left unfinished.

Professional edge finishing improves appearance and extends service life.

Edge Finishing Techniques

-

Flame polishing for clear, glossy edges

-

Mechanical polishing for thicker sheets

-

Sanding in progressive grits for matte finishes

In Kenyan retail and hospitality projects, edge quality directly affects perceived workmanship and brand image.

How Are Perspex Sheets Bent Without Cracking?

Perspex must be heated evenly before bending to prevent internal stress.

Cold bending or uneven heating leads to visible cracks and long-term failure.

Heat Bending Process

-

Controlled heating using strip heaters

-

Uniform temperature along bend line

-

Gradual bending to required angle

-

Cooling while held in position

Recommended bending temperature:

-

Approximately 150°C to 160°C, depending on thickness

BHD emphasizes proper equipment and patience, especially for thicker sheets.

What Bend Radius Should Fabricators Observe?

Every Perspex thickness has a minimum safe bend radius.

Ignoring bend radius limits compromises structural integrity.

Typical Minimum Bend Radius Guidelines

| Thickness | Minimum Bend Radius |

|---|---|

| 3 mm | 45 mm |

| 5 mm | 75 mm |

| 8 mm | 120 mm |

| 10 mm | 150 mm |

Fabricators should adjust based on:

-

Sheet formulation

-

Heating consistency

-

End-use stress exposure

How Does Kenyan Climate Affect Perspex Performance?

Kenya’s climate influences expansion, UV resistance, and long-term clarity.

Material selection and installation must account for regional conditions.

Coastal Regions

-

High humidity

-

Salt exposure

-

Elevated UV intensity

Recommendations:

-

UV-stabilized Perspex

-

Allow expansion gaps

-

Use corrosion-resistant fixings

Nairobi and Highlands

-

High daytime UV

-

Cooler nights

-

Wind exposure

Recommendations:

-

Thicker sheets for large spans

-

Proper mounting to avoid vibration stress

What Installation Practices Prevent Perspex Failure?

Incorrect installation causes more failures than material defects.

Professional mounting techniques are essential for longevity.

Best practices include:

-

Oversized holes to allow expansion

-

Rubber gaskets or spacers

-

Avoid over-tightening fasteners

-

Use compatible sealants

BHD advises installers to treat Perspex as a flexible material, not rigid glass.

How Does Regulatory Compliance Affect Perspex Projects in 2026?

Fabrication materials must now align with tax, standards, and safety regulations.

BHD supports compliance at procurement and documentation levels.

KRA eTIMS Compliance (January 2026)

-

All Perspex purchases must be supported by valid eTIMS invoices

-

Required for expense validation and audits

KEBS Standards Levy 2025

-

Confirms quality control and traceability

-

Protects buyers from substandard acrylic imports

National Building Code 2024

-

Requires performance-based material selection

-

Emphasizes safety and durability in public-facing installations

Why Kenyan Fabricators Choose BHD for Perspex Supply

Fabricators require consistent quality, accurate thickness, and reliable documentation.

BHD supplies Perspex suited for professional cutting and bending applications.

BHD advantages:

-

Fabrication-grade sheets

-

Consistent thickness tolerance

-

Bulk supply capability

-

Technical guidance

-

Regulatory-ready documentation

What Projects Benefit Most from Custom Perspex Fabrication?

Customized Perspex solutions add value where clarity, precision, and design matter.

Professional fabrication expands creative and functional possibilities.

Examples:

-

Retail counters and display units

-

Office partitions

-

Security screens

-

Signage systems

-

Architectural features

How Does Customization Reduce Long-Term Costs?

Accurate fabrication reduces waste, rework, and installation time.

This directly improves project profitability.

Cost-saving factors:

-

Fewer material replacements

-

Faster installations

-

Reduced site modifications

-

Improved client satisfaction

Final Thoughts: Precision Matters in Perspex Fabrication

Perspex sheets are only as good as the craftsmanship applied to them. In Kenya’s competitive fabrication industry, precision cutting, controlled bending, and correct installation separate professional results from costly failures.

Burhani Hardware Dealers supports Kenyan fabricators by supplying reliable Perspex materials and guiding best-practice customization methods aligned with 2026 regulatory requirements, local climate realities, and professional fabrication standards.

Contact Burhani Hardware Dealers (BHD)

Visit: Industrial Area, Funzi Road, Nairobi

Call / WhatsApp: +254 731 217 462 | +254 704 606 131

Email: burhanihardwaredealers [at] yahoo.com

Website: https://bhd.co.ke/

Leave a reply