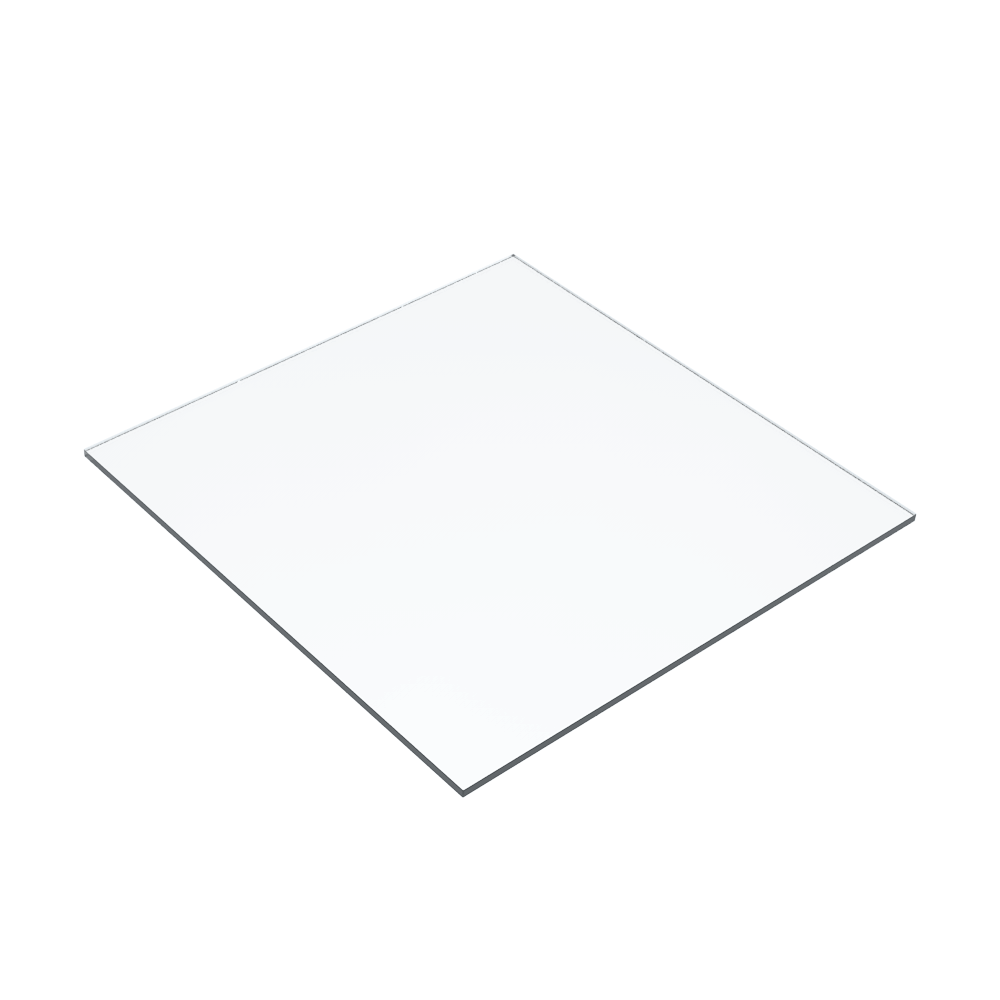

Perspex sheets are acrylic plastic glazing panels known for clarity, shatter resistance, and ease of fabrication.

They are widely used in security glazing applications where traditional glass may be inadequate due to weight, safety, or impact concerns.

Perspex is a trade name for PMMA (Polymethyl Methacrylate), which is optically clear like glass but much lighter and stronger under impact. Nairobi’s growing urban environment—with increased foot traffic, aggressive weather patterns, and security needs—makes Perspex an attractive alternative for many façade and interior glazing applications.

Why Is Security Glazing Important in Nairobi?

Security glazing enhances safety, reduces risk from break-ins or vandalism, and protects occupants and assets.

It is increasingly required in commercial, institutional, and high-end residential buildings.

Nairobi’s mixed-use districts such as Westlands, Upper Hill, Kilimani, and CBD face significant security and safety demands due to high footfall, urban crime rates, and investment in high-value properties. In addition to security concerns, glazing must:

-

Withstand day-to-day impact (accidental bumps, door swings)

-

Resist wind loads, dust, and UV exposure

-

Provide clear visibility for retail and office frontage

-

Comply with standards that govern safety and performance

Perspex sheets address many of these needs while offering design flexibility.

How Do Perspex Sheets Compare with Traditional Glass?

Perspex sheets are lighter, more impact-resistant, and easier to machine than glass.

Glass offers higher scratch resistance and is sometimes perceived as more premium—but Perspex delivers significantly better safety performance in many real-world scenarios.

Perspex vs. Glass: Key Performance Factors

| Feature | Perspex Sheets | Glass |

|---|---|---|

| Weight | ~50% lighter | Heavy |

| Impact Resistance | High (shatterproof) | Low (prone to breakage) |

| Optical Clarity | Excellent | Excellent |

| Scratch Resistance | Moderate | High |

| Thermal Expansion | Higher | Lower |

| Installation Ease | Easy to cut and fix | Requires skilled glazing |

| Safety | Safer upon impact | Sharp shards if broken |

For security glazing, impact resistance and safety are often prioritized over scratch resistance, especially in high-traffic or high-risk zones.

What Makes Perspex Sheets Ideal for Security Glazing in Nairobi?

Perspex sheets are particularly suited to Nairobi’s built environment due to their combination of safety, lightness, and adaptability.

They reduce risk, installation time, and long-term maintenance compared to glass glazing.

1. Shatterproof Safety

Unlike glass, Perspex does not break into sharp shards. In security glazing applications—such as bank vestibules, retail storefronts, and hospital reception areas—this reduces injury risk during impact events.

2. Lightweight for Structural Efficiency

Perspex weighs about half as much as glass with the same thickness, reducing load on frames and structural members—especially valuable for older buildings or lightweight framing systems.

3. High Impact Resistance

Perspex can absorb impacts that would shatter glass, making it ideal for areas prone to knocks from carts, stretchers, or doors.

4. UV Stability and Weather Performance

Quality Perspex sheets have UV-inhibited surfaces that resist yellowing and degradation—important given Nairobi’s strong equatorial sun.

5. Ease of Fabrication

Perspex cuts, drills, and routes easily, allowing for custom shapes, holes for fixings, and integration with security hardware without specialized glass‐cutting tools.

What Thicknesses of Perspex Sheets Are Best for Security Glazing?

Choosing the right thickness is key to performance, safety, and cost.

Security glazing applications generally require thicker Perspex when compared to decorative or light partitioning use.

Typical Perspex Thickness Ranges

| Application | Recommended Thickness |

|---|---|

| Light interior partitions | 3–6 mm |

| Standard window glazing | 6–8 mm |

| Security glazing (impact-resistant) | 10–12 mm+ |

| High-impact zones (public lobbies, cash zones) | 12–15 mm |

Thickness choice depends on:

-

Height of installation

-

Expected impact forces

-

Frame and fixing design

Consult a structural or glazing professional to confirm appropriate thickness for your specific project conditions.

How Do Perspex Sheets Perform Under Nairobi’s Climate?

Perspex sheets perform well under Nairobi’s equatorial weather, especially when UV-stable grades are used.

However, temperature effects and thermal expansion must be accounted for during installation.

UV Exposure

Nairobi receives intense sunlight year-round. High-quality, UV-inhibited Perspex resists yellowing and loss of clarity, even after prolonged solar exposure.

Thermal Expansion

Perspex expands more than glass with temperature changes. Proper allowance must be made at fixings to prevent buckling or stress.

Moisture and Dust

Perspex does not absorb moisture, making it resilient in Nairobi’s rainy seasons. Regular cleaning is recommended to manage dust and pollutants common in urban centers.

Installation Best Practices for Perspex Security Glazing

Proper installation ensures performance, longevity, and compliance with safety standards.

Attention to framing, fixings, and allowances for expansion is essential.

1. Use Compatible Framing Systems

Aluminum or steel frames with rubber gaskets or neoprene seals provide secure support without concentrated stress at fixings.

2. Allow Space for Expansion

Because Perspex expands with temperature changes, avoid rigid, tight fixings. Use oversized holes or compression gaskets where specified.

3. Edge Protection

Ensure edges are not exposed to abrasive contact. Chamfered or polished edges reduce crack initiation.

4. Sealants and Weatherproofing

Use compatible sealants that won’t chemically attack acrylic surfaces.

5. Professional Glazing Tools

Cutting and drilling should be done with sharp tools to prevent melting or chipping.

Perspex Sheets vs. Toughened Glass: Security Comparison

Perspex and toughened glass both improve safety over ordinary annealed glass, but they do so in different ways.

Perspex delivers superior impact resistance, while toughened glass offers higher scratch resistance and rigidity.

| Aspect | Perspex Sheets | Toughened Glass |

|---|---|---|

| Primary Safety | Shatterproof | Breaks into cubes (safer than regular glass) |

| Impact Resistance | High | Moderate |

| Weight | Lighter | Heavier |

| Installation Ease | Easier | More specialized |

| Scratch Resistance | Lower | Higher |

| Visibility | Excellent | Excellent |

For security glazing where impact resistance is the priority, Perspex is often the more reliable long-term choice.

Fire and Building Code Compliance in Kenya (2026)

Security glazing must comply with relevant building standards, safety codes, and procurement requirements.

In Kenya, 2026 compliance priorities include KEBS quality standards and the National Building Code 2024.

Standards Levy and Quality Assurance

Kenyan construction materials must meet KEBS Standards Levy 2025 requirements. Always request compliance documentation for Perspex glazing.

KRA eTIMS (Effective Jan 1, 2026)

Perspex sheet purchases used in contract works should be supported by valid eTIMS invoices to ensure deductible expenses under Kenyan tax law.

National Building Code 2024

The Code emphasizes performance-based safety for materials used in occupied spaces. Ensure Perspex glazing assemblies satisfy local fire and egress performance requirements with certified tests where needed.

Cost Considerations for Perspex Security Glazing

Perspex sheets are generally more expensive per square meter than standard glass but cheaper than some specialty security glass systems.

Lifecycle value—given lower breakage risk and lower installation complexity—can make Perspex cost-effective.

Cost drivers include:

-

Sheet thickness and grade (UV-stable, anti-scratch coatings)

-

Framing and gasket systems

-

Fabrication complexity

-

Installation labor

Get detailed project quotations before specification to compare glass, Perspex, and hybrid glazing systems.

Maintenance and Longevity of Perspex Sheets

Perspex security glazing requires simple maintenance and can last many years with minimal service.

Unlike glass, it will not shatter, but surface care is needed to manage scratches and dust.

Cleaning Best Practices

-

Use mild soap and soft cloths

-

Avoid abrasive cleaners

-

Rinse dust before wiping to reduce micro-scratches

Scratch Mitigation

Light surface scratches can sometimes be polished out with acrylic-safe compounds.

With proper cleaning and care, Perspex glazing retains clarity and strength for many years, even in urban Nairobi environments.

Common Mistakes to Avoid

Incorrect material selection or poor installation undermines security glazing performance.

Avoid these frequent pitfalls when using Perspex sheets:

-

Over-tightening fixings (prevents expansion)

-

Using non-UV-stable grades under strong sun

-

Ignoring compliance documentation

-

Installing without expansion gaps

-

Choosing thickness based on cost alone

Always consult glazing professionals and verify technical datasheets.

When Should You Choose Perspex Over Glass?

Perspex is preferable when impact resistance, safety, and weight reduction outweigh the need for absolute scratch resistance or ultra-rigid surfaces.

Ideal use cases in Nairobi include:

-

Bank teller counters and vestibules

-

Retail storefronts with high foot traffic

-

Schools and public buildings

-

Hospital and clinical reception areas

-

Interior partitions where safety is a priority

For aesthetic façades with heavy traffic and security focus, Perspex delivers peace of mind without sacrificing visibility.

Where to Buy Quality Perspex Sheets in Nairobi

Reliable sourcing ensures quality sheets, compliance documentation, and professional support.

Choose suppliers who provide technical guidance and certified materials.

For high-grade Perspex sheets suitable for security glazing applications in Nairobi and across Kenya, contact reputable construction materials dealers with strong stock and delivery capabilities.

Contact Burhani Hardware Dealers (BHD)

For premium Perspex sheets, fabrication support, and professional glazing advice:

Email: burhanihardwaredealers@yahoo.com

Call/WhatsApp: +254 731 217 462 | +254 704 606 131

Visit: BHD, Industrial Area, Funzi Road, Nairobi

Website: https://bhd.co.ke/

Delivery Guarantee:

-

Same-day delivery within Nairobi

-

Next-day delivery countrywide to Nakuru, Kisumu, Mombasa, Eldoret, Thika, Meru, Kitengela, and Malindi

Leave a reply