How to Install Alucobond Panels Safely and Correctly

Alucobond panels, also known as Aluminium Composite Panels (ACP), have become one of the most popular cladding materials in Kenya for commercial buildings, residential facades, retail centres, petrol stations, signage, and modern architectural designs. Their smooth finish, weather resistance, and long life make them a preferred choice for both interior and exterior applications.

However, proper Alucobond installation is just as important as buying quality panels. When installed correctly, ACP panels deliver long-term performance, excellent structural stability, and an appealing visual finish. When installed poorly, they can warp, leak, fade prematurely, or even detach from the building.

This comprehensive guide explains how to install Alucobond panels safely and correctly in Kenya, from site preparation to fixing and finishing. Contractors, builders, fabricators, architects, and project managers can use it as a complete reference. The guide also includes links to other complementary building materials available at BHD, including polycarbonate roofing sheets, ladders, Perspex sheets, gutters, and structural steel products widely used in façade installations.

BHD stocks high-quality Alucobond sheets for Kenyan projects. You can explore available designs, textures, and colours at https://bhd.co.ke/alucobond-sheets-in-kenya and https://bhd.co.ke/alucobond-sheets-kenya-2025.

H2: Understanding Alucobond Panels and Their Role in Construction

Alucobond is a sandwich composite material consisting of two aluminium sheets bonded to a polyethylene or mineral-filled fire-resistant core. This structure creates a panel that is lightweight yet strong, easy to fabricate, and durable in harsh weather conditions common in Kenya.

Alucobond panels are especially popular for:

-

Exterior cladding and facades

-

Interior wall decoration

-

Canopies and column covers

-

Office partitions and branding

-

Signage and advertising boards

-

Retail shop fronts and petrol station branding

Their adaptability allows contractors to combine ACP with other architectural materials such as polycarbonate sheets, Perspex sheets, WPC wall panels, gutters, steel sections, and more. For example, many contractors combine Alucobond façades with polycarbonate roofing sheets available at https://bhd.co.ke/polycarbonate-roofing-sheets.

Understanding how ACP works, how it responds to temperature, and how it should be handled is the foundation for a safe and successful installation.

H2: Tools and Safety Equipment Required for Proper Installation

Professional ACP installation requires the right tools to ensure accuracy, efficiency, and safety. Using the wrong tools can cause dents, poor cuts, and uneven edges.

Essential tools include:

-

Circular saw with carbide-tipped blade

-

Router for V-grooving and folding

-

Jigsaw or cutting blade for curved cuts

-

Measuring tape and chalk line

-

Laser level or spirit level

-

Rivet gun

-

Drilling machine with aluminium bits

-

Cladding clamps

-

Screwdrivers

-

Sealant gun

-

Ladder or access tower

For safe elevation access, always use high-quality ladders that are designed for construction tasks. You can find strong and reliable ladders at https://bhd.co.ke/ladders or https://bhd.co.ke/buy-quality-ladders-in-kenya.

Required safety equipment includes gloves, safety shoes, protective eyewear, dust masks, and ear protection. Contractors must ensure scaffolding is safely erected and the workspace is clear of debris.

For general guidance on construction materials in Kenya, visit https://bhd.co.ke/construction-materials-in-kenya.

H2: Preparing the Site for Alucobond Installation

Site preparation is one of the most important steps in ensuring correct ACP installation. Proper preparation prevents future problems such as misalignment, water leakage, buckling, or structural weakness.

Tasks during site preparation include:

-

Inspecting the building façade for cracks, loose plaster, or unstable surfaces. Any damaged areas should be repaired before installation.

-

Confirming measurements and façade layout based on architectural drawings.

-

Checking vertical and horizontal alignment to avoid installing panels on an uneven wall.

-

Marking fixing points for the subframe using a chalk line.

-

Ensuring all materials such as ACP sheets, screws, rivets, brackets, and sealants are onsite and ready.

Installers should also review the manufacturer’s specifications, site safety rules, and project documentation. For general guidance, refer to BHD’s FAQ page at https://bhd.co.ke/frequently-asked-questions.

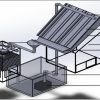

H2: Installing the Subframe Structure for Alucobond Panels

Alucobond panels should never be installed directly onto the building wall. A subframe is required to support the panels, maintain ventilation, and allow for thermal expansion.

Materials typically used to create the subframe include aluminium profiles, steel channels, square hollow sections, or rectangular hollow sections. You can explore these materials at:

-

HR Channels: https://bhd.co.ke/hr-channel-kenya

-

HR Beams: https://bhd.co.ke/hr-beams

Steps for subframe installation:

-

Fixing L-shaped brackets to the wall using approved anchor bolts.

-

Installing vertical profiles onto the brackets and checking alignment with a level.

-

Adding horizontal profiles to form a grid that will support the ACP sheets.

-

Ensuring a ventilation gap of at least 20 to 30 mm behind the panels to prevent moisture build-up.

-

Tightening all connections and ensuring the structure is rigid and stable.

A properly installed subframe ensures the panels sit flat and maintain their structural and visual quality for many years.

H2: Measuring and Cutting Alucobond Panels Correctly

Once the subframe is complete, the next step is measuring and cutting the Alucobond sheets.

Accurate measurement is essential. Contractors should measure twice and cut once to avoid wastage.

Cutting the panels requires:

-

A circular saw with aluminium blades

-

A router for V-grooves used in bending

-

A jigsaw for curved cuts

Always cut with the protective film still on the panel to avoid scratching. Make sure all panels are cut facing the same direction to avoid subtle colour differences on the façade.

Routing the back side of the panel allows it to fold smoothly during corner or edge fabrication. Routing should be consistent to achieve clean and sharp bends.

Drilling holes for rivets or screws should be done using sharp aluminium bits. The holes must be slightly larger than the fasteners to allow the panel to expand naturally with temperature changes.

Visit https://bhd.co.ke/terms-and-conditions to learn more about safe handling and material-related guidelines when purchasing from BHD.

H2: Positioning Alucobond Panels Before Fixing

Before final fixing, installers should always perform a dry installation or temporary placement of the panels.

This step involves:

-

Positioning each panel on the subframe to check alignment

-

Confirming that all edges sit flush with the subframe

-

Verifying uniform gaps between panels

-

Checking that the grain direction (for textured panels) matches the intended design

-

Confirming corner, window, and door alignments

Ensuring proper alignment during the dry fit helps avoid costly rework later in the installation process.

H2: Fixing Alucobond Panels Safely and Correctly

There are three main ways to fix ACP sheets depending on the project design, façade layout, and budget.

Method 1: Riveting

Riveting is one of the most widely used methods for ACP installations in Kenya. It is cost-effective, secure, and easy to maintain. Use colour-matched rivets or stainless-steel rivets for durability. Rivets should be evenly spaced and must not be overtightened.

Method 2: Screw Fixing

Screws are used for both interior and exterior applications. Stainless steel or aluminium screws are recommended to prevent rust. Screws should be tightened only enough to hold the panel firmly while still allowing movement for thermal expansion.

Method 3: Hanging or Clip System

This premium method uses concealed brackets that create a seamless surface without visible screws or rivets. It is commonly used in high-end buildings and malls. Panels fabricated with slots or grooves hang on rails installed onto the subframe.

During fixing, ensure:

-

All panels align with the layout

-

Fasteners are secure but not over-tightened

-

Expansion gaps of 3 to 5 mm are maintained

-

No bending or warping occurs during installation

You can find steel components used in façade applications such as MS plates, MS angles, black pipes, and other materials at:

H2: Sealing Joints and Treating Edges for Weather Resistance

Proper joint sealing is crucial for ensuring the façade remains waterproof, clean, and strong over time.

Open joints require aluminium trims to maintain consistent spacing and improve aesthetic appeal. They also allow ventilation behind the panels.

Closed joints are sealed using a high-quality silicone sealant. Before applying the sealant, installers should use masking tape on both sides of the joint to ensure clean, straight lines.

Corners are finished using folded ACP pieces or prefabricated corner caps. Edges must be trimmed, smooth, and well aligned.

If your project requires additional finishing materials such as PVC gutters or decorative wall panels, you can find them at:

For interior branding or signage requiring glossy finishes, Perspex sheets are ideal. Visit https://bhd.co.ke/premium-perspex-sheets-nairobi.

H2: Cleaning, Finishing, and Final Inspection

Once installation is complete, the protective film covering the Alucobond panels should be removed. This should be done only after all drilling, riveting, and sealing work is fully completed to prevent scratching.

Final cleaning involves using a mild detergent or ACP-approved cleaning agent. Abrasive cleaning materials should be avoided because they can damage the coating.

A final inspection should check:

-

Panel alignment

-

Straightness of joints

-

Secure fixing of fasteners

-

Clean edges and corners

-

Smooth, scratch-free surfaces

-

Consistency of colour direction

High-quality Alucobond panels and proper installation can last 20 to 30 years with minimal maintenance.

H2: Common Mistakes to Avoid When Installing Alucobond Panels

Many installation problems in Kenya occur due to improper handling or incorrect installation techniques. Avoid the following mistakes:

-

Installing ACP directly onto the wall without a subframe.

-

Cutting panels without the protective film.

-

Failing to maintain thermal expansion gaps.

-

Using substandard rivets or screws that may rust over time.

-

Overtightening fasteners which leads to buckling.

-

Ignoring the direction of the metallic finish.

-

Mixing ACP batches resulting in colour variation.

-

Working in strong winds which increases risk of damage.

-

Poor joint sealing leading to water leakage.

Learning and applying proper techniques ensures long-term durability and visual appeal.

H2: Choosing Complementary Materials for Alucobond Installations

Many façade projects combine Alucobond panels with other materials to enhance durability, improve aesthetics, or complete structural requirements.

Some commonly paired products include:

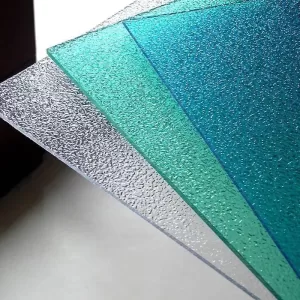

Polycarbonate sheets

These are ideal for canopies, skylights, and curved roofing. Explore options at:

https://bhd.co.ke/polycarbonate-sheets-in-kenya

https://bhd.co.ke/best-polycarbonates-in-kenya

https://bhd.co.ke/polycarbonate-sheets-price-kenya

https://bhd.co.ke/solid-polycarbonate-sheets

Perspex and decorative boards

Used for signage, branding, and interior display panels.

https://bhd.co.ke/premium-perspex-sheets-nairobi

https://bhd.co.ke/marble-boards-in-kenya

Structural steel

For support frames and reinforcement. Examples include:

https://bhd.co.ke/ms-zed-bars

https://bhd.co.ke/ms-tee

https://bhd.co.ke/tmt-bars

https://bhd.co.ke/binding-wire

https://bhd.co.ke/chequered-plates

https://bhd.co.ke/zed-purlins

Using high-quality structural materials ensures your Alucobond installation remains strong and resilient for decades.

H2: Why Buy Alucobond Panels from BHD

BHD is a trusted supplier of Alucobond panels and construction materials in Kenya. We supply contractors, builders, sign makers, architects, and homeowners across Nairobi and the entire country.

Reasons to buy from BHD:

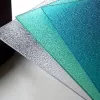

Quality Assurance

BHD provides high-grade Alucobond sheets sourced from reputable manufacturers. You get colours, thicknesses, textures, and finishes that meet international standards.

Wide Variety

Whether you need glossy, matte, metallic, mirror, brushed, or textured finishes, BHD offers a wide selection. Visit our Alucobond pages for available options:

https://bhd.co.ke/alucobond-sheets-in-kenya

https://bhd.co.ke/alucobond-sheets-kenya-2025

Reliable Supply Chain

BHD maintains strong inventory and ensures consistent availability of ACP sheets and accessories.

Nationwide Deliveries

Same-day delivery is available in Nairobi and next-day delivery for other towns across the country.

Friendly Support

Our expert team advises clients on the right materials for their projects. Learn more about us at https://bhd.co.ke/about-us-polycarbonates.

H2: Final Thoughts and Call to Action

Installing Alucobond panels safely and correctly requires the right tools, proper preparation, a strong subframe, and attention to detail during fixing and finishing. When done well, ACP installation dramatically transforms buildings, offering a modern, long-lasting facade suitable for both residential and commercial projects.

If you are looking for high-quality Alucobond panels, façade accessories, polycarbonate sheets, Perspex sheets, or structural construction materials, BHD is your trusted partner.

To place an order, request expert guidance, or get a quotation, visit our Contact Us page at https://bhd.co.ke/contact-us.

COUNTRYWIDE DELIVERIES AVAILABLE

Same-day delivery within Nairobi

Next-day delivery to all counties in Kenya

Contact us

Burhani Hardware Dealers

Email: burhanihardwaredealers [at] yahoo.com

Call or WhatsApp: +254 731 217 462 | +254 704 606 131

Visit us at: BHD, Industrial Area, Funzi Road, Nairobi

We deliver to Nairobi, Nakuru, Eldoret, Mombasa, Kisumu, Meru, Nyeri, Kitengela, Athi River, Kajiado, Thika, Machakos, Naivasha, Narok, Garissa, Kakamega, Kisii, Migori, Lamu, Malindi, Kilifi, Kwale, Voi, Emali, Isiolo, Lodwar, Moyale, Marsabit, Bungoma, Busia, Webuye, and many more towns across Kenya.

Leave a reply