MS Flat Bars in Kenya: Uses, Cost & Benefits for Construction Projects

ms-flat-bars

Steel remains the backbone of modern construction and MS flat bars are a staple product for contractors, builders, architects and DIY professionals. This long-form guide is designed to answer practical questions, help you choose the right size and grade, compare costs with alternative materials, and highlight best-fit projects where MS flat bars shine.

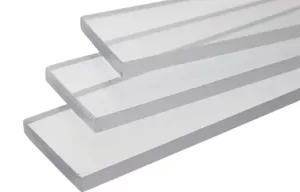

What are MS Flat Bars?

MS (Mild Steel) flat bars are simple, rectangular bars of mild steel manufactured in a range of widths and thicknesses. They are sometimes called mild steel flat bars, plain flat bars or simply flat bars. Their cross-section is rectangular and they are sold either in cut-to-size lengths or as long stock lengths depending on supplier practices.

Definition and properties

At their core, MS flat bars are low-carbon steel products with a typical carbon content that gives them a good balance of ductility, weldability and tensile strength. MS flat bars offer:

- Good weldability and formability

- Reasonable tensile strength for general structural tasks

- Compatibility with cutting, drilling, punching and bending tools

- Cost-effectiveness compared to higher-grade alloy steels

Common specifications (sizes & thickness)

MS flat bars are commonly available in widths ranging from 10 mm up to 200 mm (and beyond for special orders) with thicknesses from 3 mm up to 25 mm or more. Typical stock sizes for general construction include:

- 25 mm x 3 mm

- 40 mm x 4 mm

- 50 mm x 6 mm

- 75 mm x 8 mm

- 100 mm x 10 mm

Lengths are usually 6m or cut-to-length options; BHD can supply both stock lengths and custom-length cuts. For project-specific needs, consider the exact thickness and width that will meet load and fabrication requirements.

For stock availability and details, check BHD’s MS Flat Bars product page: MS Flat Bars.

Uses of MS Flat Bars in Construction

MS flat bars in Kenya serve many roles across residential, commercial and industrial projects. Their affordability and versatility make them a default choice for many common structure and fabrication tasks.

Roofing & Structural Support

MS flat bars are used for secondary structural members, purlin supports, roof edge framing and as stiffeners in metal roof assemblies. When paired with purlins or Zed purlins, they provide lateral support and anchorage points for roofing sheets (including polycarbonate). When you require neat, reliable support for roofing, use flat bars cut to size and fixed with appropriate fasteners and corrosion protection.

Learn about complementary roofing materials: polycarbonate roofing sheets and zed purlins from BHD.

Gates, Grills & Frames

Because of their flat, uniform surface, MS flat bars are ideal for gate panels, pedestrian and vehicle gate frames, window grills and security doors. Flat bars can be welded into frames, embellished with perforations or decorative elements, and painted or powder-coated for corrosion resistance and aesthetics. For fencing and entrance gates, they deliver a crisp modern look and strong structural performance.

Fabrication & Welding Applications

Fabricators use flat bars for brackets, braces, connectors and a wide range of fabricated assemblies. Their even thickness makes them easy to clamp, weld and machine. Flat bars also function as reinforcements in composite assemblies and as base plates for mounting equipment. For plumbing and mechanical support work, flat bars are often drilled and bolted to hold pipe clamps, machine bases and equipment mounts.

Industrial & Commercial Uses

In industrial applications, MS flat bars are used for conveyor frames, shelving, racking support, and machinery guards. They’re also useful in commercial signage, shop fixtures, and construction site temporary structures. If you combine flat bars with CHS, SHS, or HR beams you can build robust frames and supports — BHD stocks a wide range of complementary steel products such as RHS, CHS, and HR beams.

For fabricators and contractors seeking accessories, BHD supplies binding wire, ladders and other site essentials: binding wire • ladders.

Cost of MS Flat Bars in Kenya

Understanding the cost of MS flat bars in Kenya requires knowledge of material sizing, market dynamics and supply options. Flat bar prices fluctuate with steel market rates, transportation costs and supplier margins. Below we summarize the primary cost drivers and how to secure competitive pricing.

Factors influencing price (size, grade, supplier, market demand)

Key factors affecting pricing include:

- Size & thickness: Wider and thicker bars cost more per meter due to higher material volume.

- Grade: Standard mild steel is less costly than higher-carbon or alloy variants.

- Market demand: Global steel price movements, import duties and local supply chains influence retail prices.

- Supplier value-add: Cutting to length, pre-drilling, galvanizing or painting raise unit cost but save on-site labor.

- Quantity: Bulk purchases often attract lower unit prices.

Comparing costs with other steel products

Compared with HR channels, RHS, CHS or TMT bars, flat bars are typically cheaper on a per-meter basis for basic structural uses. However, when load-bearing is a primary requirement, select the right section (for example HR channel or HR beam) because choosing an under-sized flat bar to save money could be costly in structural failure or rework.

Where to buy MS Flat Bars affordably

Buy from reputable suppliers that provide clear specifications, test certifications where applicable, and value-added services. BHD offers competitive pricing and product transparency. View current prices and stock availability at: MS Flat Bars product page and explore related construction materials at construction materials in Kenya.

Durability and Strength of MS Flat Bars

One of the main reasons contractors choose MS flat bars is the balance between durability, cost and ease of use. Properly specified and protected, MS flat bars can provide decades of dependable service.

Longevity in construction projects

Longevity depends on environmental exposure and protection. In coastal or highly humid zones, surface corrosion can reduce life if left untreated. For long service life, consider galvanized flat bars, protective paint systems, or stainless alternatives for critical exposed applications.

Corrosion resistance and maintenance

Plain mild steel is susceptible to rust. For improved corrosion resistance:

- Galvanize the flat bars (hot-dip galvanizing is common).

- Apply epoxy primer and finish coats for painted protection.

- Use regular maintenance—clean, inspect and re-coat as necessary.

BHD offers finishing options and can recommend the best protective measures for your project based on location and exposure.

Load-bearing capacity

While flat bars are not a substitute for engineered beams in large-span structural work, they provide excellent load distribution in bracing, stiffeners, and mid-load applications. Always consult structural drawings or a qualified engineer to verify that selected flat bar dimensions meet load and safety requirements.

Choosing the Right MS Flat Bars for Your Project

Selecting the right flat bar requires matching the bar’s physical dimensions, mechanical properties and protective treatment to the project’s functional and environmental requirements.

Residential construction

For homes, typical uses include balcony supports, gate frames, stair stringers, handrails, and small structural reinforcements. Choose flat bars sized to the load scenario — commonly 40 mm to 100 mm widths at 4 mm to 10 mm thickness for many domestic tasks.

Commercial and industrial projects

Commercial uses often require heavier sections (thicker flat bars and sometimes fabricated assemblies) that are welded to beams or bolted into larger frames. For industrial applications involving heavy equipment supports, combine MS flat bars with RHS or HR channels for composite strength.

Aesthetic applications (interior and exterior)

Flat bars can be finished to a high standard — painted, powder-coated or polished for visible architectural features. Use them for edge trims, signage supports, and modern interior fixtures where clean lines and flat surfaces are desired.

For matching aesthetic materials and decorative panels, view BHD’s other offerings such as Premium Perspex Sheets, Marble Boards, and WPC panels: WPC Wall Panels.

Why Buy MS Flat Bars from BHD?

BHD (Burhani Hardware Dealers) has positioned itself as a trustworthy supplier of construction steel and diversified building products across Kenya. Here’s why contractors, fabricators and homeowners trust BHD for MS flat bars.

Quality assurance and variety

BHD stocks a wide range of sizes and thicknesses of MS flat bars and other complementary steel sections. Each order is checked for dimensional accuracy and quality. If you need special cutting or pre-fabrication services, BHD can assist with precision cutting to your required lengths.

Trusted by contractors nationwide

With strong relationships across Nairobi and regional contractors, BHD has delivered materials to projects of all sizes. See product categories that contractors rely upon like TMT bars, MS angle, and MS plates.

Delivery and support services

BHD offers reliable delivery services across Kenya (same-day within Nairobi and next-day to many locations). The company provides ordering flexibility — buy online, call/WhatsApp for quotations, or visit the Nairobi branch for walk-in purchases and technical consultations. You can view delivery and company terms at: Terms & Conditions, and reach out via Contact Us.

Final Thoughts & Call to Action

MS flat bars in Kenya are a practical, economical and flexible material for a wide range of construction, fabrication and architectural projects. From gates and frames to bracing and decorative elements, their adaptability makes them a go-to choice for contractors and homeowners alike. While they require appropriate selection and surface protection in corrosive environments, when correctly specified MS flat bars provide excellent long-term value.

If you’re planning a project, consider the intended use, load requirements and exposure conditions to select the correct size, thickness and finishing option. For large projects, consult a structural engineer to confirm specifications.

Ready to buy or need expert guidance? Visit BHD’s MS Flat Bars product page to check current stock and pricing: MS Flat Bars. For a wider range of construction materials, explore our collection: Construction Materials in Kenya. Have questions? See our FAQ or get in touch on the contact page: Contact Us.

COUNTRYWIDE DELIVERIES AVAILABLE

✔ Same-day delivery within Nairobi

✔ Next-day delivery to other parts of the country

We supply all types of MS Flat Bars, Polycarbonate, and Perspex Sheets — delivered right to your location!

📞 Contact us

Burhani Hardware Dealers

📧 burhanihardwaredealers [at] yahoo.com

📞 Call/WhatsApp: +254 731 217 462 | +254 704 606 131

📍 Visit: BHD, Industrial Area, Funzi Road, Nairobi

We deliver to: Nairobi, Nakuru, Kisumu, Mombasa, Malindi, Eldoret, Kisii, Migori, Moyale, Lodwar, Marsabit, Maralal, Kapenguria, Kitale, Isiolo, Rumuruti, Webuye, Bungoma, Malaba, Busia, Mumias, Kakamega, Siaya, Luanda, Bondo, Mbita, Homa Bay, Rongo, Sotik, Bomet, Narok, Kericho, Kapsabet, Gilgil, Nyahururu, Nanyuki, Meru, Thika, Maua, Chuka, Limuru, Naivasha, Kitui, Mutomo, Kajiado, Emali, Kitengela, Oloitoktok, Garissa, Mwingi, Kibwezi, Mtito Andei, Voi, Diani, Lamu, Garsen, Kilifi, Mtwapa, Mariakani, Kikuyu, Ngong, Karen, Athi River — and many more!

Leave a reply